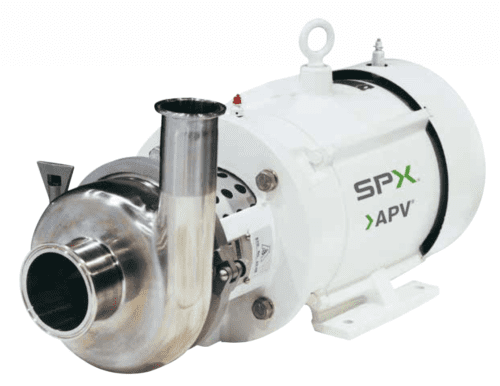

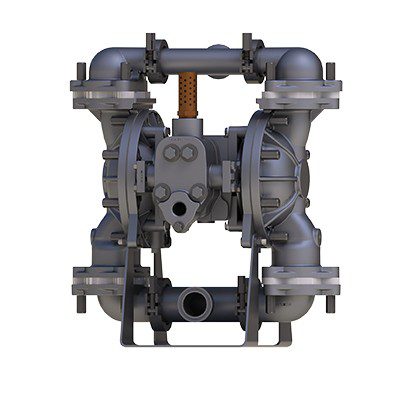

The 200LR Series Liquid Ring Pump handles products with entrained air as well as maintaining its prime when other pumps become air bound. This feature makes the 200LR the best choice for complete emptying of tanks and lines during normal process or CIP.

In addition to being an excellent CIP return pump, the 200LR can run in either direction, making it possible to fill or empty tanks with the same pump.

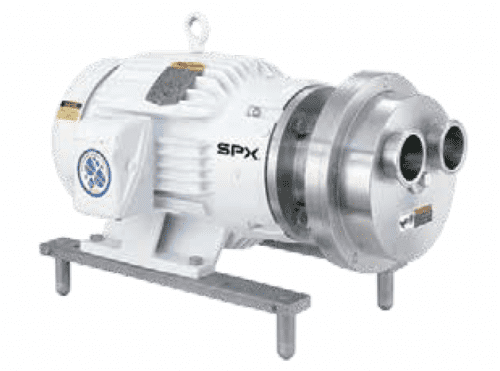

THE 200LR SERIES OFFERS:

- Less overhead space needed due to both suction and discharge ports being on the front cover

- Same seal(s) as used in 200 Series Centrifugal Pumps

- Reduced noise levels

- Stainless steel motor adapter is standard.

- JM Motor and no stub shaft eliminates need to check TIR (Total Indicated Run-out).