-

The Series 20/21 resilient seated butterfly valve surpasses the high standards required in sanitary valve applications, and inherent flow characteristics and capabilities. Bray's Series 20 valve is a wafer version with flange locating holes, and the Series 21 is the companion lug version for dead-end service and other flange requirements.

The Series 20/21 resilient seated butterfly valve surpasses the high standards required in sanitary valve applications, and inherent flow characteristics and capabilities. Bray's Series 20 valve is a wafer version with flange locating holes, and the Series 21 is the companion lug version for dead-end service and other flange requirements. -

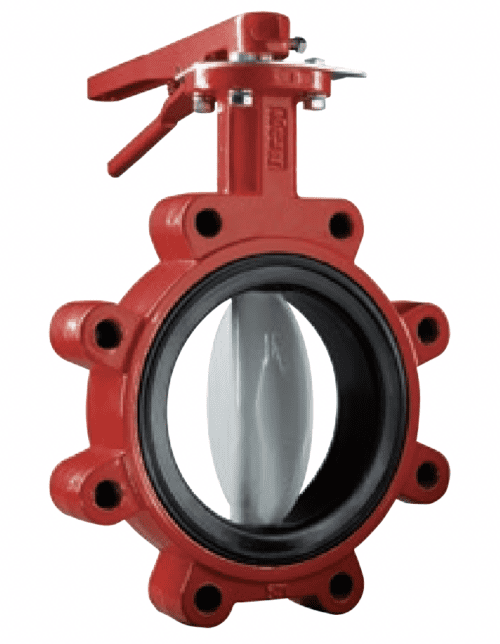

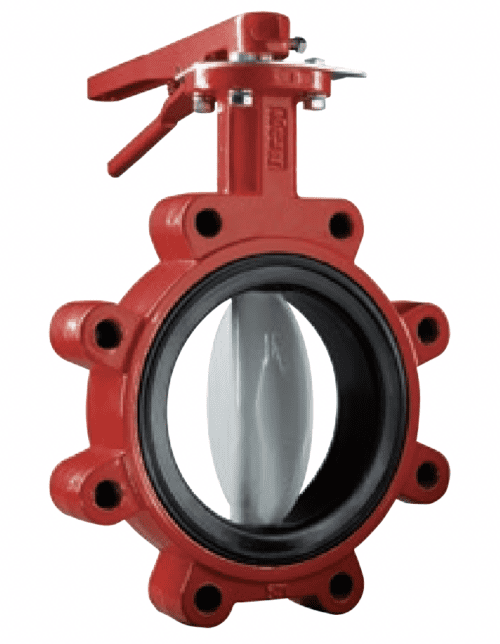

The Bray Series 30 Wafer and Series 31 Lug style resilient seated butterfly valves feature a one-piece body with a high-strength through stem design utilizing an internal disc to stem connection.The Series 30/31 is engineered to provide bidirectional bubble-tight shutoff and isolation of the line media from the stem or valve body. Available with a wide selection of high-quality resilient seat & disc materials for a variety of applications, our Series 30/31 butterfly valves are easily automated for on-off or modulating service. "

The Bray Series 30 Wafer and Series 31 Lug style resilient seated butterfly valves feature a one-piece body with a high-strength through stem design utilizing an internal disc to stem connection.The Series 30/31 is engineered to provide bidirectional bubble-tight shutoff and isolation of the line media from the stem or valve body. Available with a wide selection of high-quality resilient seat & disc materials for a variety of applications, our Series 30/31 butterfly valves are easily automated for on-off or modulating service. " -

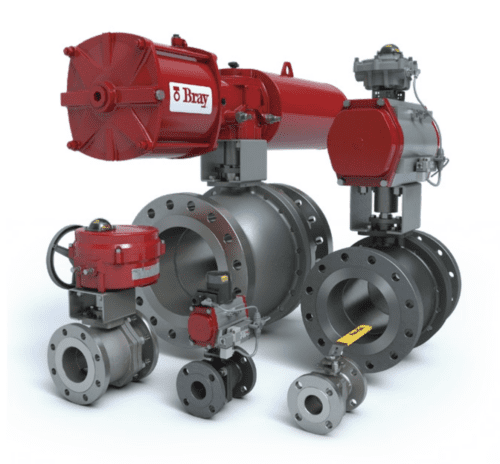

The Series 5000/6000 3-piece ball valves offer the convenience of a three piece body design at an economical price. The three piece design with a swing out center section allows for ease of in-line and out-of-line maintenance. Standard valve bodies are investment cast CF8M Stainless Steel or WCB Carbon Steel. All body castings are marked with a foundry heat number for full traceability.

The Series 5000/6000 3-piece ball valves offer the convenience of a three piece body design at an economical price. The three piece design with a swing out center section allows for ease of in-line and out-of-line maintenance. Standard valve bodies are investment cast CF8M Stainless Steel or WCB Carbon Steel. All body castings are marked with a foundry heat number for full traceability. -

The Series 7000/8000 3-piece ball valves offer the highest flexibility in the Bray product line for selection of end connections, seat materials and three piece design. To meet customer demands for a valve with the widest possible range of applications, these valves can be fitted with control or tri-ported balls (for full cavity drainage), as well as cavity fillers for special service requirements.

The Series 7000/8000 3-piece ball valves offer the highest flexibility in the Bray product line for selection of end connections, seat materials and three piece design. To meet customer demands for a valve with the widest possible range of applications, these valves can be fitted with control or tri-ported balls (for full cavity drainage), as well as cavity fillers for special service requirements. -

Brawn Mixer BWG Series industrial mixers are a versatile solution for applications where headroom or other constraints require a compact mixer package. The BWG Series features a worm gear drive in a right angle configuration that brings reliable performance to applications at low speed, making it ideal for applications such as flocculation or polymer blending.

Brawn Mixer BWG Series industrial mixers are a versatile solution for applications where headroom or other constraints require a compact mixer package. The BWG Series features a worm gear drive in a right angle configuration that brings reliable performance to applications at low speed, making it ideal for applications such as flocculation or polymer blending. -

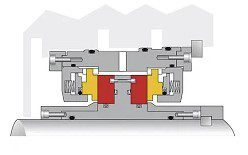

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries. The fully hydraulically balanced design promotes a reliable valve that prevents hydraulic blocking and withstands pressure spikes, enabling flexible bi-directional non-slamming flow

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries. The fully hydraulically balanced design promotes a reliable valve that prevents hydraulic blocking and withstands pressure spikes, enabling flexible bi-directional non-slamming flow -

Series F15/F30 flanged ball valves are engineered to ensure bubble-tight shutoff and low operating torque. ½” – 2” sizes feature Flow-Tek's Smart Stem technology with integral live load packing. 2 ½” – 12” valves utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life. Larger sized valves feature a trunnion-type ball support to reduce operating torque.

Series F15/F30 flanged ball valves are engineered to ensure bubble-tight shutoff and low operating torque. ½” – 2” sizes feature Flow-Tek's Smart Stem technology with integral live load packing. 2 ½” – 12” valves utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life. Larger sized valves feature a trunnion-type ball support to reduce operating torque. -

Airfin Coolers from Flowserve are easy to install and clean, and have lower maintenance and operating costs. Available in natural-convection and forced-air designs, Airfin Coolers use atmospheric air as the coolant, eliminating the need for cooling water. They are constructed with corrosion-resistant materials for use in most chemical services.

Airfin Coolers from Flowserve are easy to install and clean, and have lower maintenance and operating costs. Available in natural-convection and forced-air designs, Airfin Coolers use atmospheric air as the coolant, eliminating the need for cooling water. They are constructed with corrosion-resistant materials for use in most chemical services. -

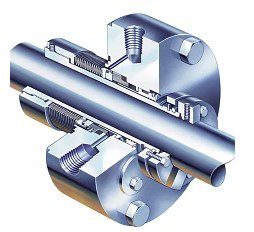

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682H Seal Cooler is our most advanced option, ideal for operations requiring the highest reliability, corrosion resistance and performance, and the lowest maintenance costs. The unit has multiple internal baffles to maximize heat transfer and can be disassembled in the field for easy cleaning and inspection. It is available in series or parallel flow configurations.

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682H Seal Cooler is our most advanced option, ideal for operations requiring the highest reliability, corrosion resistance and performance, and the lowest maintenance costs. The unit has multiple internal baffles to maximize heat transfer and can be disassembled in the field for easy cleaning and inspection. It is available in series or parallel flow configurations. -

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682L Seal Cooler is our most cost-effective option for applications requiring less cooling or heat transfer. It has a welded shell and is available in a series flow, single-coil configuration.

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682L Seal Cooler is our most cost-effective option for applications requiring less cooling or heat transfer. It has a welded shell and is available in a series flow, single-coil configuration. -

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682M Seal Cooler is our mid-level option, ideal for operations that want to balance cost with ease of maintenance. Maintenance teams can disassemble the unit in the field for easy cleaning and inspection. The 682M Seal Cooler is available in series or parallel flow configurations.

Flowserve’s 682 Seal Cooler family uses “shell and tube” systems with optimized baffling that lowers the fluid temperature passing through the tubing while minimizing scaling and fouling of the water passing through the shell. Compatible with single or dual mechanical seals, 682 Seal Coolers are utilized as standalone units or part of a comprehensive piping plan package. The 682M Seal Cooler is our mid-level option, ideal for operations that want to balance cost with ease of maintenance. Maintenance teams can disassemble the unit in the field for easy cleaning and inspection. The 682M Seal Cooler is available in series or parallel flow configurations. -

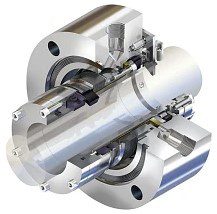

The 682-53B seal system is Flowserve’s most popular solution for dual mechanical seal barrier fluid systems. Designed to meet the rigorous demands of the oil and gas, refinery and petrochemical industries, it is optimized for value and reliability. Also, it can be assembled regionally with shorter lead times.

The 682-53B seal system is Flowserve’s most popular solution for dual mechanical seal barrier fluid systems. Designed to meet the rigorous demands of the oil and gas, refinery and petrochemical industries, it is optimized for value and reliability. Also, it can be assembled regionally with shorter lead times. -

The AFC Seal Cooler is a forced draft system that increases performance of finned pipe designs by boosting airflow across the cooling coil. It increases mechanical seal reliability by removing heat and reducing fluid temperature without cooling water.The AFC Seal Cooler can be applied to multiple seal support systems, including piping plans 21, 23, 53B and 53C.

The AFC Seal Cooler is a forced draft system that increases performance of finned pipe designs by boosting airflow across the cooling coil. It increases mechanical seal reliability by removing heat and reducing fluid temperature without cooling water.The AFC Seal Cooler can be applied to multiple seal support systems, including piping plans 21, 23, 53B and 53C. -

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient.

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient. -

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient.

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient. -

The 682-53B dual seal barrier system is Flowserve’s most popular solution for mechanical seal barrier fluid systems. It’s available as an assembled to order (ATO) product available from key global production locations with standardized components and pre-engineered configurations and packages. ATO products benefit you with faster quotation, reduced lead times and lower costs.

The 682-53B dual seal barrier system is Flowserve’s most popular solution for mechanical seal barrier fluid systems. It’s available as an assembled to order (ATO) product available from key global production locations with standardized components and pre-engineered configurations and packages. ATO products benefit you with faster quotation, reduced lead times and lower costs. -

Designed for piping plans 52 and 53A, the 682R series buffer/barrier fluid reservoir provides an ideal supply of clean, cool and reliable working fluid to maximize dual mechanical seal life and reliability. The Flowserve 682R seal reservoir is compliant with API 682 4th Edition and designed to provide the quickest delivery and most competitive pricing while offering a wide range of popular options. Pre-configured options include elliptical or flanged bottom, pressure and level transmitters or switches, hand pump and stand.

Designed for piping plans 52 and 53A, the 682R series buffer/barrier fluid reservoir provides an ideal supply of clean, cool and reliable working fluid to maximize dual mechanical seal life and reliability. The Flowserve 682R seal reservoir is compliant with API 682 4th Edition and designed to provide the quickest delivery and most competitive pricing while offering a wide range of popular options. Pre-configured options include elliptical or flanged bottom, pressure and level transmitters or switches, hand pump and stand. -

BRC Series edge-welded metal bellows seals are exceptionally robust and designed to seal high-temperature hydrocarbons, heat transfer fluids and severe services in refineries and hydrocarbon processing plants. The BRC series is fully compliant with API 682 Type C requirements and features thick-plate Alloy 718 bellows convolutions for superior corrosion resistance.

BRC Series edge-welded metal bellows seals are exceptionally robust and designed to seal high-temperature hydrocarbons, heat transfer fluids and severe services in refineries and hydrocarbon processing plants. The BRC series is fully compliant with API 682 Type C requirements and features thick-plate Alloy 718 bellows convolutions for superior corrosion resistance. -

BX Series balanced metal bellows seals are engineered to drive exceptional, long-term equipment reliability and lower energy consumption. They provide exceptional reliability in corrosive and non-corrosive fluids, especially fluids that crystallize or coke in atmospheric conditions. The BX Series is fully compliant with API 682 Type B requirements. Available in single and dual seal configurations.

BX Series balanced metal bellows seals are engineered to drive exceptional, long-term equipment reliability and lower energy consumption. They provide exceptional reliability in corrosive and non-corrosive fluids, especially fluids that crystallize or coke in atmospheric conditions. The BX Series is fully compliant with API 682 Type B requirements. Available in single and dual seal configurations. -

BXHHS and BXRH seals provide sealing capability at extreme temperatures in challenging refinery and petrochemical services. When pumping services push beyond temperature limits of elastomers, BXHHS and BXRH seals offer reliable sealing in both single and dual seal configurations. BXHHS and BXRH seals are fully compliant with API 682 Type C requirements.

BXHHS and BXRH seals provide sealing capability at extreme temperatures in challenging refinery and petrochemical services. When pumping services push beyond temperature limits of elastomers, BXHHS and BXRH seals offer reliable sealing in both single and dual seal configurations. BXHHS and BXRH seals are fully compliant with API 682 Type C requirements. -

Circpac MD seals are a segmented circumferential seal designed for fans, blowers, dryers, turbines, centrifuges and other rotating equipment. Circpac MD seals come packaged in a convenient split housing for easy installation. Standard designs consistently outperform packing, bushings, labyrinths, and felt seals with lower gas consumption over a wider range of operating conditions.

-

Circpac MD seals are a segmented circumferential seal designed for fans, blowers, dryers, turbines, centrifuges and other rotating equipment. Circpac MD seals come packaged in a convenient split housing for easy installation. Standard designs consistently outperform packing, bushings, labyrinths, and felt seals with lower gas consumption over a wider range of operating conditions.

-

GLS, GSS, and GSG Series seals are designed to fit the unique installation envelop and operating speeds present in integrally geared pumps and compressors. GLS seals are suitable for operating on liquid, whereas GSS seals are designed for operating in gaseous environments. GSG seals are applied at the bottom of vertical gearboxes to seal gearbox oil in and keep contaminants out.

GLS, GSS, and GSG Series seals are designed to fit the unique installation envelop and operating speeds present in integrally geared pumps and compressors. GLS seals are suitable for operating on liquid, whereas GSS seals are designed for operating in gaseous environments. GSG seals are applied at the bottom of vertical gearboxes to seal gearbox oil in and keep contaminants out. -

GSL Series seals are non-contacting gas seals for dry running vapor containment and full pressure wet backup sealing in light hydrocarbons, crude oil, and hazardous services. GSL seals use wave pattern technology to eliminate wear and are fully compliant with API 682 Type A, Arrangement 2 requirements.

GSL Series seals are non-contacting gas seals for dry running vapor containment and full pressure wet backup sealing in light hydrocarbons, crude oil, and hazardous services. GSL seals use wave pattern technology to eliminate wear and are fully compliant with API 682 Type A, Arrangement 2 requirements. -

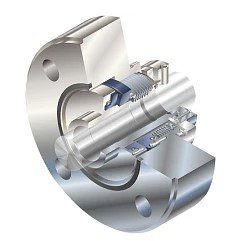

HSH seals are built for extended reliability in high pressure, high speed and highly viscous services such as mainline crude oil pipeline pumps. HSH seals are balanced, flexible stator cartridge seals with drive mechanisms and seal face geometries engineered for high torque loads and long-term performance. The HSH seal is fully compliant with API 682 Type A requirements.

HSH seals are built for extended reliability in high pressure, high speed and highly viscous services such as mainline crude oil pipeline pumps. HSH seals are balanced, flexible stator cartridge seals with drive mechanisms and seal face geometries engineered for high torque loads and long-term performance. The HSH seal is fully compliant with API 682 Type A requirements. -

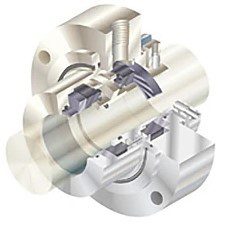

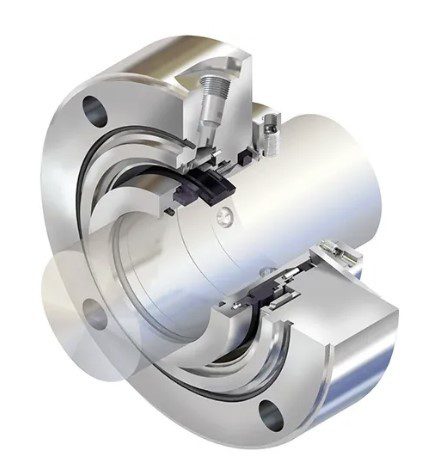

The Flowserve ISC2 Series is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for hundreds of pump models from global manufacturers. Facilities will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life.

The Flowserve ISC2 Series is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for hundreds of pump models from global manufacturers. Facilities will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life. -

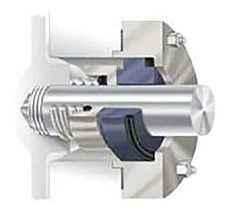

The ISC2-682 Series is a family of balanced pusher and metal bellows seals designed to fully comply with the design and qualification requirements of API 682. Platform flexibility allows application in a range of services throughout refineries, petrochemical plants and other industries where the API 682 specification is invoked. ISC2-682 seals are fully compliant with API 682, Type A and Type B requirements.

The ISC2-682 Series is a family of balanced pusher and metal bellows seals designed to fully comply with the design and qualification requirements of API 682. Platform flexibility allows application in a range of services throughout refineries, petrochemical plants and other industries where the API 682 specification is invoked. ISC2-682 seals are fully compliant with API 682, Type A and Type B requirements. -

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal.

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal.