-

This legendary pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1" S1F Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. It offers air-side interchangeability with SANDPIPER’s S15, S20 and S30 pumps for reduced inventory costs. The durable, bolted construction of the S1F is superior to the clamped-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen.

This legendary pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1" S1F Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. It offers air-side interchangeability with SANDPIPER’s S15, S20 and S30 pumps for reduced inventory costs. The durable, bolted construction of the S1F is superior to the clamped-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. -

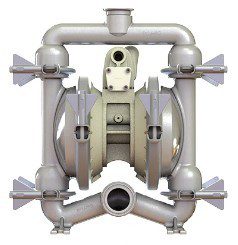

The SANDPIPER S20 non-metallic air-operated double-diaphragm (AODD) pump’s time-tested, rugged design exclusively features three-piece bolted manifolds that enable reorientation of the porting connections to suit the unique needs of your process. This pump is ideal for chemical transfer, bulk transfer and a wide variety of process applications.

The SANDPIPER S20 non-metallic air-operated double-diaphragm (AODD) pump’s time-tested, rugged design exclusively features three-piece bolted manifolds that enable reorientation of the porting connections to suit the unique needs of your process. This pump is ideal for chemical transfer, bulk transfer and a wide variety of process applications. -

The SANDPIPER 2" S20 Evolution Metallic AODD Pump is the highest-performing and most efficient AODD pump on the market. Equipped to handle abrasive fluids and suspended solids, this versatile and mobile pump has best-in-class flow rates and the lowest air consumption available. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

The SANDPIPER 2" S20 Evolution Metallic AODD Pump is the highest-performing and most efficient AODD pump on the market. Equipped to handle abrasive fluids and suspended solids, this versatile and mobile pump has best-in-class flow rates and the lowest air consumption available. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves. -

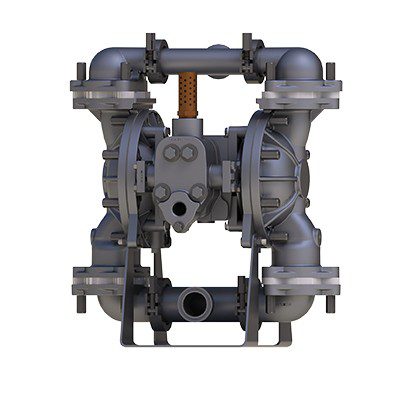

The SANDPIPER 3" S30 Evolution Metallic AODD Pump is the highest-performing and most efficient AODD pump in its class. This versatile pump is equipped to handle abrasive fluids and suspended solids. With class-leading max flow rate and the lowest air consumption available, the performance of this 3" AODD pump is unsurpassed. The durable, bolted construction of the S30 AODD pump is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

The SANDPIPER 3" S30 Evolution Metallic AODD Pump is the highest-performing and most efficient AODD pump in its class. This versatile pump is equipped to handle abrasive fluids and suspended solids. With class-leading max flow rate and the lowest air consumption available, the performance of this 3" AODD pump is unsurpassed. The durable, bolted construction of the S30 AODD pump is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves. -

The SANDPIPER WR10 ?" (10 mm) Non-Metallic Standard-Duty AODD Pump is the ideal solution when high performance and dependability are required from a small and compact pump. This portable AODD pump shares similar envelope dimensions with a standard ¼" pump, but has almost double the flow rate. It features a patented air valve system to provide non-stalling, non-icing, lube-free operation for years of dependable service. The pump is fitted with spring-loaded check valves, which enable it to be mounted in any position to suit application needs: upright, sideways and even inverted. The manifolds rotate 90?, so you can adjust the pump’s porting orientation as needed. Available in both polypropylene and PVDF (Kynar) materials of construction, this small, yet powerful pump is ideally suited for dispensing inks, coatings, car wash chemicals, paints, oils, adhesives and other chemicals.

The SANDPIPER WR10 ?" (10 mm) Non-Metallic Standard-Duty AODD Pump is the ideal solution when high performance and dependability are required from a small and compact pump. This portable AODD pump shares similar envelope dimensions with a standard ¼" pump, but has almost double the flow rate. It features a patented air valve system to provide non-stalling, non-icing, lube-free operation for years of dependable service. The pump is fitted with spring-loaded check valves, which enable it to be mounted in any position to suit application needs: upright, sideways and even inverted. The manifolds rotate 90?, so you can adjust the pump’s porting orientation as needed. Available in both polypropylene and PVDF (Kynar) materials of construction, this small, yet powerful pump is ideally suited for dispensing inks, coatings, car wash chemicals, paints, oils, adhesives and other chemicals. -

The SANDPIPER ¼" (6 mm) air-operated double-diaphragm (AODD) pump is engineered with original equipment manufacturers (OEMs) in mind and provides tremendous system flexibility. The PB ¼" is one of the quietest and most flexible AODD pumps in the compact class. Featuring a patented air valve system, this AODD pump provides non-stalling, non-icing, lube-free operation for years of dependable service. The suction and discharge manifolds have multiple porting options. Available in polypropylene, conductive acetal and PVDF (Kynar) materials of construction, this small, yet powerful pump is ideally suited for dispensing inks, coatings, paints, adhesives, oils and other chemicals.

The SANDPIPER ¼" (6 mm) air-operated double-diaphragm (AODD) pump is engineered with original equipment manufacturers (OEMs) in mind and provides tremendous system flexibility. The PB ¼" is one of the quietest and most flexible AODD pumps in the compact class. Featuring a patented air valve system, this AODD pump provides non-stalling, non-icing, lube-free operation for years of dependable service. The suction and discharge manifolds have multiple porting options. Available in polypropylene, conductive acetal and PVDF (Kynar) materials of construction, this small, yet powerful pump is ideally suited for dispensing inks, coatings, paints, adhesives, oils and other chemicals. -

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1/2” S05 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. This pumps offers a wide range of performance and application capabilities. The durable, bolted construction of the S05 is superior to the clamp-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’S original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership. Only SANDPIPER's ESADS+ feature allows complete ADS without removing the pump from service. Repair or clean in 5 minutes vs. 55 minutes for competitors.

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1/2” S05 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. This pumps offers a wide range of performance and application capabilities. The durable, bolted construction of the S05 is superior to the clamp-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’S original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership. Only SANDPIPER's ESADS+ feature allows complete ADS without removing the pump from service. Repair or clean in 5 minutes vs. 55 minutes for competitors. -

This legendary pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump performing across a wide variety of markets and applications reliably for decades. The SANDPIPER ½" S05 Metallic AODD Pump provides portability, versatility and power in a compact design. The S05 is equipped to handle abrasive fluids and small suspended solids with ease and dependability. The durable bolted construction of the S05 is superior to the clamped-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen (if you require your pump to be driven by natural gas, check out the SANDPIPER G05 pump).

This legendary pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump performing across a wide variety of markets and applications reliably for decades. The SANDPIPER ½" S05 Metallic AODD Pump provides portability, versatility and power in a compact design. The S05 is equipped to handle abrasive fluids and small suspended solids with ease and dependability. The durable bolted construction of the S05 is superior to the clamped-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen (if you require your pump to be driven by natural gas, check out the SANDPIPER G05 pump). -

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER ¾" S07 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. The trihedral valve option provides unique handling capabilities that prevent damage and move products gently. The durable bolted construction of the S07 is superior to the clamped -band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’S original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER ¾" S07 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. The trihedral valve option provides unique handling capabilities that prevent damage and move products gently. The durable bolted construction of the S07 is superior to the clamped -band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’S original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership. -

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1" S10 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. The durable, bolted construction of the S10 is superior to the clamped-band construction pump, providing exceptional performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’s original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

This pump has proven itself as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER 1" S10 Non-Metallic AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. The durable, bolted construction of the S10 is superior to the clamped-band construction pump, providing exceptional performance. This pump is designed to be driven by compressed air or nitrogen. TRUST IN A SIMPLE DESIGN SANDPIPER’s original air distribution system (ADS) is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership. -

This rugged pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER S15 Non-Metallic 1½" AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. It offers air-side interchangeability with SANDPIPER’s 1" (S1F), 2" (S20) and 3"(S30) pumps for reduced inventory costs. The durable, bolted construction of the S15 is superior to the clamped-band construction pump, providing exceptional leak-free performance. This general transfer pump is designed to be driven by compressed air or nitrogen.

This rugged pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The SANDPIPER S15 Non-Metallic 1½" AODD Pump provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. It offers air-side interchangeability with SANDPIPER’s 1" (S1F), 2" (S20) and 3"(S30) pumps for reduced inventory costs. The durable, bolted construction of the S15 is superior to the clamped-band construction pump, providing exceptional leak-free performance. This general transfer pump is designed to be driven by compressed air or nitrogen. -

The SANDPIPER 1½" S15 Metallic AODD Pump provides superior suction lift of greater than 22 ft (6.7 m). Designed for outstanding operation, this versatile and mobile pump is perfect for OEM applications. Equipped to handle abrasive fluids and suspended solids, it gives exceptional performance in harsh chemical applications where reliability is critical. Additionally, this AODD pump offers air-side interchangeability with SANDPIPER’s S20 and S30 pumps for ease of inventory management and reduced inventory costs. The durable, bolted construction of the S15 is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

The SANDPIPER 1½" S15 Metallic AODD Pump provides superior suction lift of greater than 22 ft (6.7 m). Designed for outstanding operation, this versatile and mobile pump is perfect for OEM applications. Equipped to handle abrasive fluids and suspended solids, it gives exceptional performance in harsh chemical applications where reliability is critical. Additionally, this AODD pump offers air-side interchangeability with SANDPIPER’s S20 and S30 pumps for ease of inventory management and reduced inventory costs. The durable, bolted construction of the S15 is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves. -

This legendary 1" pump has stood the test of time as a class-leading, trusted air-operated double-diaphragm (AODD) pump for a variety of markets and applications. It provides portability and versatility. It is equipped to handle abrasive fluids and suspended solids. The SANDPIPER 1" S1F Metallic AODD Pump offers air-side interchangeability with SANDPIPER’s S15, S20 and S30 pumps for reduced inventory costs. This pump is designed to be driven by compressed air or nitrogen. If your pump needs to be driven by natural gas, check out the SANDPIPER G1F pump. The durable, bolted construction of the S1F is superior to the clamped-band construction pump, providing exceptional leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

This legendary 1" pump has stood the test of time as a class-leading, trusted air-operated double-diaphragm (AODD) pump for a variety of markets and applications. It provides portability and versatility. It is equipped to handle abrasive fluids and suspended solids. The SANDPIPER 1" S1F Metallic AODD Pump offers air-side interchangeability with SANDPIPER’s S15, S20 and S30 pumps for reduced inventory costs. This pump is designed to be driven by compressed air or nitrogen. If your pump needs to be driven by natural gas, check out the SANDPIPER G1F pump. The durable, bolted construction of the S1F is superior to the clamped-band construction pump, providing exceptional leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves. -

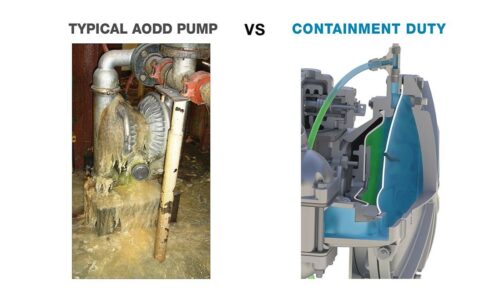

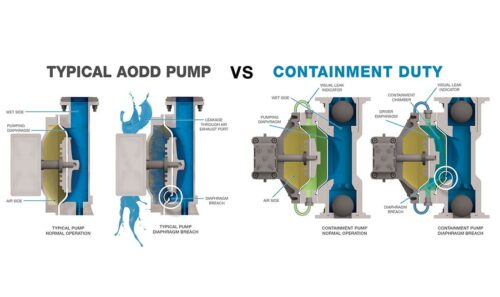

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER S20 Non-Metallic 2" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. TYPICAL PUMP VERSUS CONTAINMENT-DUTY PUMP In a typical AODD pump, when the pumping diaphragm is breached, the fluid enters the air distribution system and escapes into the environment through the muffler, requiring immediate service. In a containment-duty pump, when the pumping diaphragm is breached, the fluid enters the containment chamber and visual indicator sight tubes, alerting the user. The fluid is fully contained so the pump can continue running until the operation is complete or maintenance can be scheduled. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental Concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER S20 Non-Metallic 2" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. TYPICAL PUMP VERSUS CONTAINMENT-DUTY PUMP In a typical AODD pump, when the pumping diaphragm is breached, the fluid enters the air distribution system and escapes into the environment through the muffler, requiring immediate service. In a containment-duty pump, when the pumping diaphragm is breached, the fluid enters the containment chamber and visual indicator sight tubes, alerting the user. The fluid is fully contained so the pump can continue running until the operation is complete or maintenance can be scheduled. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental Concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER S30 Non-Metallic 3" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. Designed to handle high volumes of caustics and chemicals, the flow rate of this pump is up to 280 gpm (1,060 lpm). This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER S30 Non-Metallic 3" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. Designed to handle high volumes of caustics and chemicals, the flow rate of this pump is up to 280 gpm (1,060 lpm). This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

The SANDPIPER 1" SB1 Heavy-Duty Ball Pump is an exclusive design to SANDPIPER and is best-in-class for moving thin-highly viscous and small, solids-laden fluids. The 1" metallic heavy-duty ball pump provides excellent suction lift capabilities and is designed to withstand the most rugged, harsh ball valve pumping applications. This flexible, durable pump offers a range of features. The SB1 also has a variety of porting options, which optimize performance and make installation easy. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area, and are designed to outlast standard pumps. SB1 PUMP FEATURES EXTERNALLY SERVICEABLE AIR DISTRIBUTION SYSTEM When dirty air enters an AODD pump, it will require frequent servicing of the air distribution system. SANDPIPER is the only AODD pump manufacturer to offer an externally serviceable air distribution system (ESADS+), which allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors), reducing your downtime by as much as 90%.

The SANDPIPER 1" SB1 Heavy-Duty Ball Pump is an exclusive design to SANDPIPER and is best-in-class for moving thin-highly viscous and small, solids-laden fluids. The 1" metallic heavy-duty ball pump provides excellent suction lift capabilities and is designed to withstand the most rugged, harsh ball valve pumping applications. This flexible, durable pump offers a range of features. The SB1 also has a variety of porting options, which optimize performance and make installation easy. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area, and are designed to outlast standard pumps. SB1 PUMP FEATURES EXTERNALLY SERVICEABLE AIR DISTRIBUTION SYSTEM When dirty air enters an AODD pump, it will require frequent servicing of the air distribution system. SANDPIPER is the only AODD pump manufacturer to offer an externally serviceable air distribution system (ESADS+), which allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors), reducing your downtime by as much as 90%. -

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER ST1 AODD pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER ST1 AODD pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1½", metallic AODD pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1½", metallic AODD pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

The SANDPIPER 2" heavy-duty non-metallic flap valve pump has been designed to solve the most common challenges in mine dewatering, sump and chemical transfer applications. The robust, yet lightweight design allows for ease of maintenance and movement. This unique pump, ideal for handling solids and corrosive fluids, has been engineered to fully function in any position. It has durable mounting feet and includes lifting handles and hanging points–making it a perfect solution for numerous applications.

The SANDPIPER 2" heavy-duty non-metallic flap valve pump has been designed to solve the most common challenges in mine dewatering, sump and chemical transfer applications. The robust, yet lightweight design allows for ease of maintenance and movement. This unique pump, ideal for handling solids and corrosive fluids, has been engineered to fully function in any position. It has durable mounting feet and includes lifting handles and hanging points–making it a perfect solution for numerous applications. -

SANDPIPER’s exclusive 1½" heavy-duty ball pump provides excellent suction lift capabilities and is designed to withstand the most rugged and harsh ball valve pumping applications. The compact 1½" metallic pump has thick-walled construction and is part of our Evolution portfolio improvement. This means this pump has been optimized for the maximum amount of flow capacity with the least amount of air/gas consumption. The 1½" heavy-duty ball pump is available with a side-ported option, which makes installation easy, optimizes performance on the pumped fluid and solves critical pumping problems. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications. A SANDPIPER EXCLUSIVE: EXTERNALLY SERVICEABLE AIR DISTRIBUTION SYSTEM SANDPIPER is the only AODD pump manufacturer to offer ESADS+, which allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors), reducing your downtime by as much as 90%. WHAT IS EVOLUTION OPTIMIZED PERFORMANCE? These pumps have undergone an engineering EVOLUTION, leveraging trusted and proven product designs to improve their performance through advanced engineering methods. Optimize performance without sacrificing proven reliability.

SANDPIPER’s exclusive 1½" heavy-duty ball pump provides excellent suction lift capabilities and is designed to withstand the most rugged and harsh ball valve pumping applications. The compact 1½" metallic pump has thick-walled construction and is part of our Evolution portfolio improvement. This means this pump has been optimized for the maximum amount of flow capacity with the least amount of air/gas consumption. The 1½" heavy-duty ball pump is available with a side-ported option, which makes installation easy, optimizes performance on the pumped fluid and solves critical pumping problems. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications. A SANDPIPER EXCLUSIVE: EXTERNALLY SERVICEABLE AIR DISTRIBUTION SYSTEM SANDPIPER is the only AODD pump manufacturer to offer ESADS+, which allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors), reducing your downtime by as much as 90%. WHAT IS EVOLUTION OPTIMIZED PERFORMANCE? These pumps have undergone an engineering EVOLUTION, leveraging trusted and proven product designs to improve their performance through advanced engineering methods. Optimize performance without sacrificing proven reliability. -

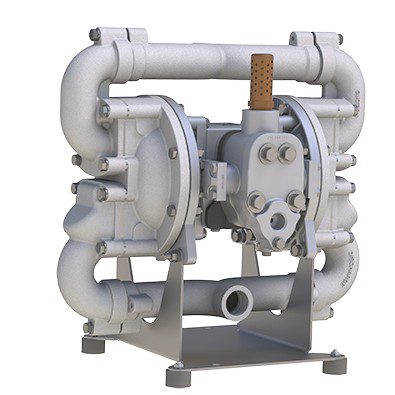

The exclusive SANDPIPER 2" HDB2 Evolution Heavy-Duty Ball Pump is a mainstay in challenging customer applications, moving thin-highly viscous and small, solids-laden fluids. The 2" metallic pump provides excellent durability in demanding applications and is designed to withstand the most rugged and harsh ball valve environments. The HDB2 is available in top- and down-porting options, which make installation easy and optimize performance on the pumped fluid. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area. They are designed to outlast standard pumps. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications.

The exclusive SANDPIPER 2" HDB2 Evolution Heavy-Duty Ball Pump is a mainstay in challenging customer applications, moving thin-highly viscous and small, solids-laden fluids. The 2" metallic pump provides excellent durability in demanding applications and is designed to withstand the most rugged and harsh ball valve environments. The HDB2 is available in top- and down-porting options, which make installation easy and optimize performance on the pumped fluid. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area. They are designed to outlast standard pumps. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications. -

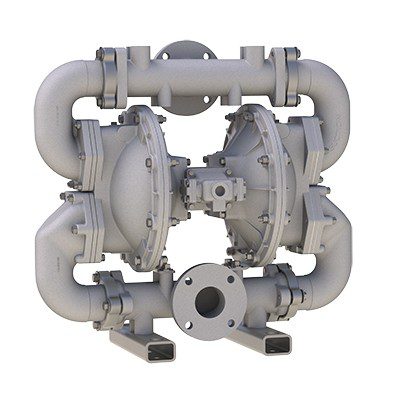

The exclusive SANDPIPER 3" HDB3 and 4" HDB4 Evolution Heavy-Duty Ball Pumps are the best in class for moving thin-highly viscous and small, solids-laden fluids. These pumps have the AODD pump industry’s highest maximum flow, with up to 300 gpm. They provide excellent suction lift capabilities and are designed to withstand the most rugged and harsh ball valve pumping applications. All SANDPIPER heavy-duty ball pumps are ATEX-certified. The HDB3 and HDB4 are available in top- and down-ported options for optimized performance. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area. They are designed to outlast standard pumps. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications.

The exclusive SANDPIPER 3" HDB3 and 4" HDB4 Evolution Heavy-Duty Ball Pumps are the best in class for moving thin-highly viscous and small, solids-laden fluids. These pumps have the AODD pump industry’s highest maximum flow, with up to 300 gpm. They provide excellent suction lift capabilities and are designed to withstand the most rugged and harsh ball valve pumping applications. All SANDPIPER heavy-duty ball pumps are ATEX-certified. The HDB3 and HDB4 are available in top- and down-ported options for optimized performance. These porting configurations solve critical problems, such as solids and abrasives settling out of the liquid chamber into the ball check area. They are designed to outlast standard pumps. These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications. -

The flexible, portable and lightweight design of the SANDPIPER HDF1 heavy-duty flap valve pump offers maximum convenience when faced with the most common challenges in sump applications, mine dewatering and any liquid application involving solids. The HDF1 has a superior flow rate to all other 1" AODD pumps and is a proven and trusted solution even in the harshest applications, effortlessly moving abrasive slurries, suspended and non-suspended solids and line-size solids. SMALL BUT MIGHTY PUMP The SANDPIPER pump design offers a small footprint, making it an excellent choice for both portable and permanent applications. The superior suction lift capabilities, combined with its solids-handling capabilities, make it the ideal solution for sump and dewatering applications. The bottom discharge porting prevents settling solids from damaging the diaphragm and shortening the pump life. HDF1 pumps are thick wall-constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves.

The flexible, portable and lightweight design of the SANDPIPER HDF1 heavy-duty flap valve pump offers maximum convenience when faced with the most common challenges in sump applications, mine dewatering and any liquid application involving solids. The HDF1 has a superior flow rate to all other 1" AODD pumps and is a proven and trusted solution even in the harshest applications, effortlessly moving abrasive slurries, suspended and non-suspended solids and line-size solids. SMALL BUT MIGHTY PUMP The SANDPIPER pump design offers a small footprint, making it an excellent choice for both portable and permanent applications. The superior suction lift capabilities, combined with its solids-handling capabilities, make it the ideal solution for sump and dewatering applications. The bottom discharge porting prevents settling solids from damaging the diaphragm and shortening the pump life. HDF1 pumps are thick wall-constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. -

The SANDPIPER 2" heavy-duty flap valve pump has a proven design that solves the most common challenges in sump applications, mine dewatering and any liquid application involving solids. This metallic air-operated double-diaphragm (AODD) pump is recommended for abrasive slurries, suspended and non-suspended solids and line-size solids. It is configured with bottom discharge porting to prevent settling solids from shortening pump life and provide superior suction lift. HDF2 pumps are thick-wall constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. The HDF2 pump has been optimized for performance as part of the SANDPIPER Evolution portfolio improvement. This efficient pump experienced a 49% flow rate increase, with a new maximum flow rate of up to 208 gpm (788 lpm).

The SANDPIPER 2" heavy-duty flap valve pump has a proven design that solves the most common challenges in sump applications, mine dewatering and any liquid application involving solids. This metallic air-operated double-diaphragm (AODD) pump is recommended for abrasive slurries, suspended and non-suspended solids and line-size solids. It is configured with bottom discharge porting to prevent settling solids from shortening pump life and provide superior suction lift. HDF2 pumps are thick-wall constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. The HDF2 pump has been optimized for performance as part of the SANDPIPER Evolution portfolio improvement. This efficient pump experienced a 49% flow rate increase, with a new maximum flow rate of up to 208 gpm (788 lpm). -

SANDPIPER has your pumping solution for fluids containing up to 3"/4" line-size solids! The SANDPIPER HDF3 and HDF4 heavy-duty flap valve pumps have a proven design that solves the most common challenges in sump applications, mine dewatering and any liquid application involving solids. These air-operated double-diaphragm (AODD) pumps are recommended for abrasive slurries, suspended and non-suspended solids and up to 3"/4" line-size solids. The heavy-duty flap valve pumps are configured with bottom discharge porting to provide superior suction lift and prevent settling solids from shortening pump life. DESIGNED FOR TOUGH APPLICATIONS AND MAXIMUM EFFICIENCY HDF3 and HDF4 pumps are thick wall-constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. HDF3 and HDF4 pump designs have recently been optimized for performance as part of the SANDPIPER Evolution portfolio improvement. These efficient pumps experienced a 19% flow rate increase, with a new maximum flow rate of up to 310 gpm (1,173 lpm). KEY ADVANTAGES Line-size solids handling (Flap valve versus ball valve pumps) Flap check valve pumps: A large flow area allows up to 3"/4" line-size solids to pass directly through the pump. Additionally, bottom discharge porting allows settling solids to pass through the pump and not settle inside the pumping chamber, preventing damage and premature wear. Ball check valve pumps: Much less flow area for solids to pass through. Large solids get stuck in the suction manifold and small solids can settle in the outer chamber–both issues affect pump performance. Superior suction lift (Flap valve versus ball valve pumps) Suction lift advantage: SANDPIPER’s flap valve design provides superior suction lift capabilities up to 24 ft in water. Diaphragm placement and flap valve seating combine to create a unit capable of suction lifts 15% greater than ball valve pumps. Dry prime: These capabilities are from a dry prime, making the SANDPIPER flap valve pump an excellent solution for situations where limited choices are available for pump priming.

SANDPIPER has your pumping solution for fluids containing up to 3"/4" line-size solids! The SANDPIPER HDF3 and HDF4 heavy-duty flap valve pumps have a proven design that solves the most common challenges in sump applications, mine dewatering and any liquid application involving solids. These air-operated double-diaphragm (AODD) pumps are recommended for abrasive slurries, suspended and non-suspended solids and up to 3"/4" line-size solids. The heavy-duty flap valve pumps are configured with bottom discharge porting to provide superior suction lift and prevent settling solids from shortening pump life. DESIGNED FOR TOUGH APPLICATIONS AND MAXIMUM EFFICIENCY HDF3 and HDF4 pumps are thick wall-constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. HDF3 and HDF4 pump designs have recently been optimized for performance as part of the SANDPIPER Evolution portfolio improvement. These efficient pumps experienced a 19% flow rate increase, with a new maximum flow rate of up to 310 gpm (1,173 lpm). KEY ADVANTAGES Line-size solids handling (Flap valve versus ball valve pumps) Flap check valve pumps: A large flow area allows up to 3"/4" line-size solids to pass directly through the pump. Additionally, bottom discharge porting allows settling solids to pass through the pump and not settle inside the pumping chamber, preventing damage and premature wear. Ball check valve pumps: Much less flow area for solids to pass through. Large solids get stuck in the suction manifold and small solids can settle in the outer chamber–both issues affect pump performance. Superior suction lift (Flap valve versus ball valve pumps) Suction lift advantage: SANDPIPER’s flap valve design provides superior suction lift capabilities up to 24 ft in water. Diaphragm placement and flap valve seating combine to create a unit capable of suction lifts 15% greater than ball valve pumps. Dry prime: These capabilities are from a dry prime, making the SANDPIPER flap valve pump an excellent solution for situations where limited choices are available for pump priming. -

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1½" S15 Non-Metallic AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks, and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1½" S15 Non-Metallic AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks, and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

For more than 55 years, manufacturers across multiple industries utilizing hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1" S1F Non-Metallic AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

For more than 55 years, manufacturers across multiple industries utilizing hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped. The SANDPIPER 1" S1F Non-Metallic AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached. This leak-free pump is designed to be driven by compressed air or nitrogen. WHY USE CONTAINMENT-DUTY PUMPS? Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids. Paints, inks and coatings Adhesives and resins Chemicals and petrochemicals Oils and hydrocarbons Acids, caustics and corrosives Plastics and polymers Contaminated water and wastewater Pesticides and herbicides Fertilizers Preservatives Mercury Phthalates High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit. Drugs and pharmaceuticals Foods Cyanotic-based paints Precious metal-based fluids Cosmetics Perfumes Printer inks Beer and alcohol Blood Creams and lotions Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need. -

The SH2-M pump is a 2:1 ratio, high-pressure, single-acting diaphragm pump powered via compressed air. As the only high-pressure, air-operated diaphragm flap valve pump in the world, the unit can deliver discharge pressures twice the inlet pressure up to 250 psig (17.2 barg). The pump can be utilized in filter press feeds and other demanding applications requiring higher discharge pressures and/or solids handling that most air-operated single-diaphragm (AOD) pumps are not capable of achieving. This pump is engineered with metallic seats and heavy-duty flap valves to help ensure a durable valve seal for performance in high-pressure applications. Unlike other high-pressure pumps on the market, the SANDPIPER SH2-M unit features a balanced diaphragm design. This design allows for a minimal pressure differential across the diaphragm, helping to decrease the need for replacement parts–this effectively decreases downtime and ultimately lowers the total cost of ownership. The SH2-M high-pressure pump is available in both aluminum and cast iron with various diaphragm (elastomer) options.

The SH2-M pump is a 2:1 ratio, high-pressure, single-acting diaphragm pump powered via compressed air. As the only high-pressure, air-operated diaphragm flap valve pump in the world, the unit can deliver discharge pressures twice the inlet pressure up to 250 psig (17.2 barg). The pump can be utilized in filter press feeds and other demanding applications requiring higher discharge pressures and/or solids handling that most air-operated single-diaphragm (AOD) pumps are not capable of achieving. This pump is engineered with metallic seats and heavy-duty flap valves to help ensure a durable valve seal for performance in high-pressure applications. Unlike other high-pressure pumps on the market, the SANDPIPER SH2-M unit features a balanced diaphragm design. This design allows for a minimal pressure differential across the diaphragm, helping to decrease the need for replacement parts–this effectively decreases downtime and ultimately lowers the total cost of ownership. The SH2-M high-pressure pump is available in both aluminum and cast iron with various diaphragm (elastomer) options. -

The EH2-M pump is a 2:1 ratio high-pressure pump powered via compressed air. Capable of delivering discharge pressures twice the inlet pressure up to 250 psig (17.2 barg), the EH2-M pump is designed for durability. The pump can be utilized in demanding applications, such as filter press feeds, as well as other critical applications requiring higher discharge pressures most air-operated diaphragm (AOD) pumps aren’t capable of achieving. This pump is engineered to include weighted check balls and metallic seats to help ensure a robust and durable valve seal for performance in high-pressure applications. Unlike other high-pressure pumps on the market, the SANDPIPER EH2-M unit features a balanced diaphragm design. This design allows for a minimal pressure differential across the diaphragm, helping to decrease the need for replacement parts—effectively decreasing downtime and, ultimately, lowering the total cost of ownership. The EH2-M high-pressure pump is available in cast iron and stainless steel with various diaphragm (elastomer) options.

The EH2-M pump is a 2:1 ratio high-pressure pump powered via compressed air. Capable of delivering discharge pressures twice the inlet pressure up to 250 psig (17.2 barg), the EH2-M pump is designed for durability. The pump can be utilized in demanding applications, such as filter press feeds, as well as other critical applications requiring higher discharge pressures most air-operated diaphragm (AOD) pumps aren’t capable of achieving. This pump is engineered to include weighted check balls and metallic seats to help ensure a robust and durable valve seal for performance in high-pressure applications. Unlike other high-pressure pumps on the market, the SANDPIPER EH2-M unit features a balanced diaphragm design. This design allows for a minimal pressure differential across the diaphragm, helping to decrease the need for replacement parts—effectively decreasing downtime and, ultimately, lowering the total cost of ownership. The EH2-M high-pressure pump is available in cast iron and stainless steel with various diaphragm (elastomer) options. -

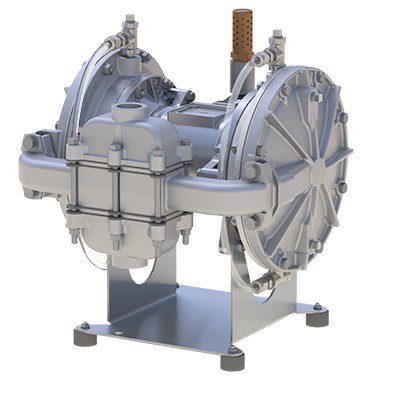

The SANDPIPER HP10 1" (25 mm) Metallic 2:1 High-Pressure Pump provides nearly double the force in applications where pressure is priority and excellent flow rates are a must. This high-pressure air pump is ideal for thick, viscous fluids (high specific gravity), high head pressure applications, and moving fluids a long distance. Incorporating two additional air chambers and one extra air side driver diaphragm, doubles the surface area on which air pressure is exerted. This magnifies the force by nearly doubling the air inlet pressure. The magnified pressure is delivered directly to the pumped fluid via the fluid diaphragms. SANDPIPER AODD pumps achieve high discharge pressures and excellent flow rates.

The SANDPIPER HP10 1" (25 mm) Metallic 2:1 High-Pressure Pump provides nearly double the force in applications where pressure is priority and excellent flow rates are a must. This high-pressure air pump is ideal for thick, viscous fluids (high specific gravity), high head pressure applications, and moving fluids a long distance. Incorporating two additional air chambers and one extra air side driver diaphragm, doubles the surface area on which air pressure is exerted. This magnifies the force by nearly doubling the air inlet pressure. The magnified pressure is delivered directly to the pumped fluid via the fluid diaphragms. SANDPIPER AODD pumps achieve high discharge pressures and excellent flow rates. -

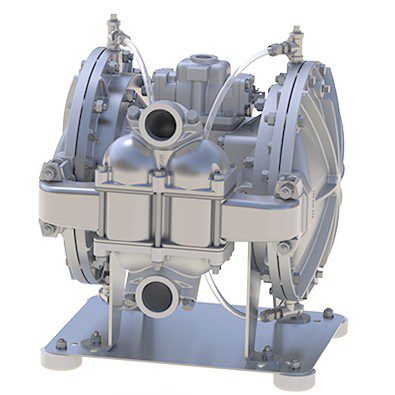

The SANDPIPER HP20 2" (50 mm) Metallic 2:1 High-Pressure Pump provides nearly double the force in applications where pressure is priority and excellent flow rates are a must. This high-pressure air pump is ideal for thick, viscous fluids (high specific gravity), high head pressure applications, and moving fluids a long distance. Incorporating two additional air chambers and one extra air side driver diaphragm, doubles the surface area on which air pressure is exerted. This magnifies the force by nearly doubling the air inlet pressure. The magnified pressure is delivered directly to the pumped fluid via the fluid diaphragms. SANDPIPER AODD pumps achieve high discharge pressures and excellent flow rates.

The SANDPIPER HP20 2" (50 mm) Metallic 2:1 High-Pressure Pump provides nearly double the force in applications where pressure is priority and excellent flow rates are a must. This high-pressure air pump is ideal for thick, viscous fluids (high specific gravity), high head pressure applications, and moving fluids a long distance. Incorporating two additional air chambers and one extra air side driver diaphragm, doubles the surface area on which air pressure is exerted. This magnifies the force by nearly doubling the air inlet pressure. The magnified pressure is delivered directly to the pumped fluid via the fluid diaphragms. SANDPIPER AODD pumps achieve high discharge pressures and excellent flow rates. -

SANDPIPER’s SSB1 and DSB1 1" AODD pumps have been the ideal choice for pharmaceutical, nutraceutical and personal care pumping applications for more than 30 years. These robust ball valve pumps are constructed from polished 316 stainless steel and feature FDA-compliant nitrile diaphragms and check balls. The tri-clamp construction makes these pumps easily compatible with your sanitary system design. PUMPS FOR SANITARY APPLICATIONS The DSB1, a highly polished version of the SSB1, is available with an electronic leak detector, providing the ultimate in leak protection and clean pumping with the paired performance of AODD pump technology. Known for durability and cleanliness, these 1" FDA-compliant pumps are versatile and are regularly used in applications ranging from transfer of hot cooking oils to heparin production. These pumps are designed to be driven by compressed air or nitrogen.

SANDPIPER’s SSB1 and DSB1 1" AODD pumps have been the ideal choice for pharmaceutical, nutraceutical and personal care pumping applications for more than 30 years. These robust ball valve pumps are constructed from polished 316 stainless steel and feature FDA-compliant nitrile diaphragms and check balls. The tri-clamp construction makes these pumps easily compatible with your sanitary system design. PUMPS FOR SANITARY APPLICATIONS The DSB1, a highly polished version of the SSB1, is available with an electronic leak detector, providing the ultimate in leak protection and clean pumping with the paired performance of AODD pump technology. Known for durability and cleanliness, these 1" FDA-compliant pumps are versatile and are regularly used in applications ranging from transfer of hot cooking oils to heparin production. These pumps are designed to be driven by compressed air or nitrogen. -

The SANDPIPER SSB2 hygienic pump has been the ideal choice for pharmaceutical, nutraceutical and personal care pumping applications for more than 30 years. This robust AODD pump is constructed from polished 316 stainless steel and features FDA-compliant nitrile diaphragms and check balls. The tri-clamp construction makes this pump easily compatible with your sanitary system design. BROAD APPLICATIONS FOR SSB2 PUMP Known for durability and cleanliness, this versatile FDA-compliant pump is frequently used in applications ranging from processing of cooking oils to heparin production. This pump is designed to be driven by compressed air or nitrogen.

The SANDPIPER SSB2 hygienic pump has been the ideal choice for pharmaceutical, nutraceutical and personal care pumping applications for more than 30 years. This robust AODD pump is constructed from polished 316 stainless steel and features FDA-compliant nitrile diaphragms and check balls. The tri-clamp construction makes this pump easily compatible with your sanitary system design. BROAD APPLICATIONS FOR SSB2 PUMP Known for durability and cleanliness, this versatile FDA-compliant pump is frequently used in applications ranging from processing of cooking oils to heparin production. This pump is designed to be driven by compressed air or nitrogen. -

The SANDPIPER T30 3" FDA-compliant and EC 1935-certified ball valve pump is ideally suited for a variety of food and beverage processing, pharmaceutical and cosmetic industry applications. It offers the largest capacity in the SANDPIPER T-Series family of FDA pumps and provides a bolted, leak-free design.

-

TSA2 2" FDA-compliant AODD flap valve pumps are ideal for fluids containing large solids, shear-sensitive materials or slurries. This unique sanitary pump uses wide-opening flap check valves in place of small-clearance ball check valves, so line-size solids will pass through easily. This AODD pump features top suction and bottom discharge so gravity assists with solids passage. Ball valve pumps resist gravity and instead discharge out of the top, which allows settling solids to remain stuck inside the pump.

TSA2 2" FDA-compliant AODD flap valve pumps are ideal for fluids containing large solids, shear-sensitive materials or slurries. This unique sanitary pump uses wide-opening flap check valves in place of small-clearance ball check valves, so line-size solids will pass through easily. This AODD pump features top suction and bottom discharge so gravity assists with solids passage. Ball valve pumps resist gravity and instead discharge out of the top, which allows settling solids to remain stuck inside the pump. -

The SANDPIPER F05 ½" & F10 1" are FDA-compliant pumps and EC 1935 certified for food-contacting materials. These ball valve pumps are ideally suited for a variety of food and beverage processing, pharmaceutical and cosmetic industry applications where electropolished surfaces are required. As AODD pumps that are part of the SANDPIPER FB-Series family of FDA pumps.

-

The SANDPIPER F15 1½", F20 2" & F30 3" are FDA-compliant pumps and EC 1935 certified for food-contacting materials. These clamped ball valve pumps are ideally suited for a variety of food and beverage processing, pharmaceutical and cosmetic industry applications where clamped-construction pumps are necessary for quick, daily teardowns for COP (clean-out-of-place) operations.

The SANDPIPER F15 1½", F20 2" & F30 3" are FDA-compliant pumps and EC 1935 certified for food-contacting materials. These clamped ball valve pumps are ideally suited for a variety of food and beverage processing, pharmaceutical and cosmetic industry applications where clamped-construction pumps are necessary for quick, daily teardowns for COP (clean-out-of-place) operations. -

SANDPIPER FB-Series air-operated double-diaphragm (AODD) pumps are the trusted solution for applications where highly polished (shiny) surface finishes are required. The sanitary and hygienic pumps offer exceptional cleanability, ease of maintenance and superior reliability. FDA-compliant pumps, the F15C and F20C models are built for food processing and personal care applications and offer these features and benefits. 3-A CERTIFICATION With the addition of SANDPIPER’s leak detection system and with the unique one-piece integral-bonded plate PTFE diaphragms, these pumps have been specifically designed to meet the 3-A sanitary standards for AODD pumps.