-

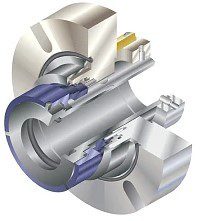

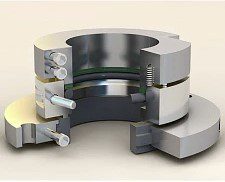

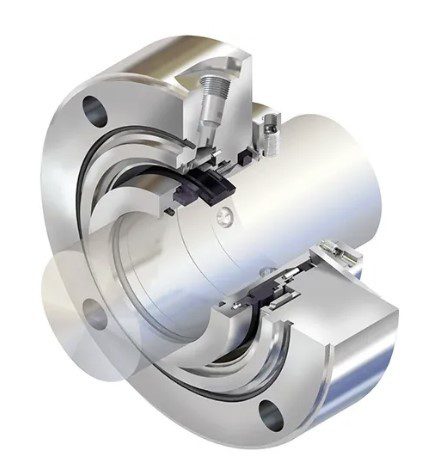

The Flowserve ISC2 Series is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for hundreds of pump models from global manufacturers. Facilities will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life.

The Flowserve ISC2 Series is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for hundreds of pump models from global manufacturers. Facilities will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life. -

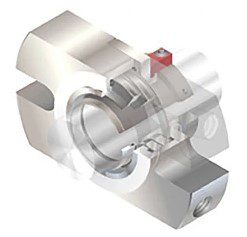

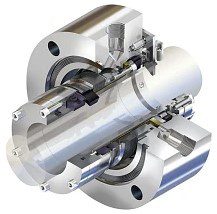

Circpac MD seals are a segmented circumferential seal designed for fans, blowers, dryers, turbines, centrifuges and other rotating equipment. Circpac MD seals come packaged in a convenient split housing for easy installation. Standard designs consistently outperform packing, bushings, labyrinths, and felt seals with lower gas consumption over a wider range of operating conditions.

-

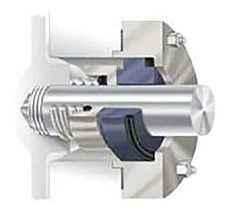

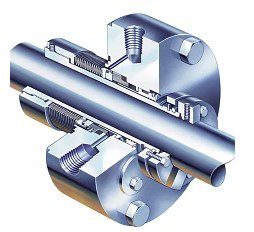

Pac-Seal elastomeric bellows component seals are designed to meet a wide variation of applications. Flowserve believes seal excellence starts with superior design and materials. That's why Pac-Seal mechanical seals are made with using the latest engineering technology to analyze and design solutions for our customer’s most challenging applications. Our experience with diverse materials including elastomers, plastics, exotic alloys and seal face materials makes Pac-Seal mechanical seals an industry leader focused on total cost of ownership.

-

Circpac MD seals are a segmented circumferential seal designed for fans, blowers, dryers, turbines, centrifuges and other rotating equipment. Circpac MD seals come packaged in a convenient split housing for easy installation. Standard designs consistently outperform packing, bushings, labyrinths, and felt seals with lower gas consumption over a wider range of operating conditions.

-

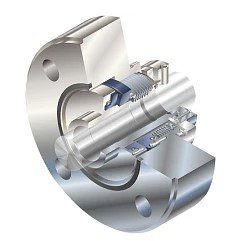

The PSS 4-61 split seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how PSS 4-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation.

The PSS 4-61 split seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how PSS 4-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation. -

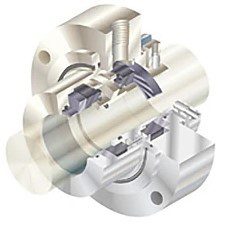

GLS, GSS, and GSG Series seals are designed to fit the unique installation envelop and operating speeds present in integrally geared pumps and compressors. GLS seals are suitable for operating on liquid, whereas GSS seals are designed for operating in gaseous environments. GSG seals are applied at the bottom of vertical gearboxes to seal gearbox oil in and keep contaminants out.

GLS, GSS, and GSG Series seals are designed to fit the unique installation envelop and operating speeds present in integrally geared pumps and compressors. GLS seals are suitable for operating on liquid, whereas GSS seals are designed for operating in gaseous environments. GSG seals are applied at the bottom of vertical gearboxes to seal gearbox oil in and keep contaminants out. -

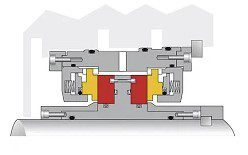

The ISC2-682 Series is a family of balanced pusher and metal bellows seals designed to fully comply with the design and qualification requirements of API 682. Platform flexibility allows application in a range of services throughout refineries, petrochemical plants and other industries where the API 682 specification is invoked. ISC2-682 seals are fully compliant with API 682, Type A and Type B requirements.

The ISC2-682 Series is a family of balanced pusher and metal bellows seals designed to fully comply with the design and qualification requirements of API 682. Platform flexibility allows application in a range of services throughout refineries, petrochemical plants and other industries where the API 682 specification is invoked. ISC2-682 seals are fully compliant with API 682, Type A and Type B requirements. -

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal.

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal. -

The ISC2-PX-61 cartridge seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how ISC2-PX-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation.

The ISC2-PX-61 cartridge seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how ISC2-PX-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation. -

UC Series seals are balanced pusher seals with a substantial single coil spring that provides exceptional performance in the most demanding services including refineries, pipelines, and petrochemical services. UC seals are fully compliant with API 682, Type A requirements. D Series seals are based on the UC Series, and add a pumping ring built into the rotating seal face body that establishes an exclusive Plan 23 cooling chamber around the seal faces. D Series seals excel in high temperature boiler feed water and hot hydrocarbon services.

UC Series seals are balanced pusher seals with a substantial single coil spring that provides exceptional performance in the most demanding services including refineries, pipelines, and petrochemical services. UC seals are fully compliant with API 682, Type A requirements. D Series seals are based on the UC Series, and add a pumping ring built into the rotating seal face body that establishes an exclusive Plan 23 cooling chamber around the seal faces. D Series seals excel in high temperature boiler feed water and hot hydrocarbon services. -

HSH seals are built for extended reliability in high pressure, high speed and highly viscous services such as mainline crude oil pipeline pumps. HSH seals are balanced, flexible stator cartridge seals with drive mechanisms and seal face geometries engineered for high torque loads and long-term performance. The HSH seal is fully compliant with API 682 Type A requirements.

HSH seals are built for extended reliability in high pressure, high speed and highly viscous services such as mainline crude oil pipeline pumps. HSH seals are balanced, flexible stator cartridge seals with drive mechanisms and seal face geometries engineered for high torque loads and long-term performance. The HSH seal is fully compliant with API 682 Type A requirements. -

RO Pusher Seals - A simple, proven and rugged design with dependability that has made it a favorite choice of maintenance personnel to seal ANSI chemical pumps. Heavy cross sections of the rotary components resist high levels of corrosion. Utilizing a simple rugged open rotary unit design, aggressive, abrasive and viscous fluids can be sealed easier than with other ANSI seal types that incorporate shrouded spring rotaries.

RO Pusher Seals - A simple, proven and rugged design with dependability that has made it a favorite choice of maintenance personnel to seal ANSI chemical pumps. Heavy cross sections of the rotary components resist high levels of corrosion. Utilizing a simple rugged open rotary unit design, aggressive, abrasive and viscous fluids can be sealed easier than with other ANSI seal types that incorporate shrouded spring rotaries. -

RA Pusher Seals - A single balanced seal designed to mount outside the seal chamber. No wetted metal parts (RA-C) reduce seal costs for highly corrosive services, especially on non-metallic pumps. Installs easily on the outside of the seal chamber and is suitable for metallic and nonmetallic equipment such as plastic, glass, and lined designs.

RA Pusher Seals - A single balanced seal designed to mount outside the seal chamber. No wetted metal parts (RA-C) reduce seal costs for highly corrosive services, especially on non-metallic pumps. Installs easily on the outside of the seal chamber and is suitable for metallic and nonmetallic equipment such as plastic, glass, and lined designs. -

The QB-61 pusher seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how QB-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation.

The QB-61 pusher seal has undergone rigorous testing and evaluation by NSF International and has been NSF/ANSI/CAN 61 & 372 certified for applications that involve drinking water, from the source to the tap. The NSF certifications cover all wetted components of the seal and demonstrate how QB-61 seals meet regulatory requirements for drinking water quality, giving municipalities confidence in safe seal selection and operation. -

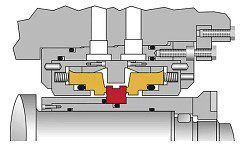

BX Series balanced metal bellows seals are engineered to drive exceptional, long-term equipment reliability and lower energy consumption. They provide exceptional reliability in corrosive and non-corrosive fluids, especially fluids that crystallize or coke in atmospheric conditions. The BX Series is fully compliant with API 682 Type B requirements. Available in single and dual seal configurations.

BX Series balanced metal bellows seals are engineered to drive exceptional, long-term equipment reliability and lower energy consumption. They provide exceptional reliability in corrosive and non-corrosive fluids, especially fluids that crystallize or coke in atmospheric conditions. The BX Series is fully compliant with API 682 Type B requirements. Available in single and dual seal configurations. -

BXHHS and BXRH seals provide sealing capability at extreme temperatures in challenging refinery and petrochemical services. When pumping services push beyond temperature limits of elastomers, BXHHS and BXRH seals offer reliable sealing in both single and dual seal configurations. BXHHS and BXRH seals are fully compliant with API 682 Type C requirements.

BXHHS and BXRH seals provide sealing capability at extreme temperatures in challenging refinery and petrochemical services. When pumping services push beyond temperature limits of elastomers, BXHHS and BXRH seals offer reliable sealing in both single and dual seal configurations. BXHHS and BXRH seals are fully compliant with API 682 Type C requirements. -

BRC Series edge-welded metal bellows seals are exceptionally robust and designed to seal high-temperature hydrocarbons, heat transfer fluids and severe services in refineries and hydrocarbon processing plants. The BRC series is fully compliant with API 682 Type C requirements and features thick-plate Alloy 718 bellows convolutions for superior corrosion resistance.

BRC Series edge-welded metal bellows seals are exceptionally robust and designed to seal high-temperature hydrocarbons, heat transfer fluids and severe services in refineries and hydrocarbon processing plants. The BRC series is fully compliant with API 682 Type C requirements and features thick-plate Alloy 718 bellows convolutions for superior corrosion resistance. -

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal.

Based on the popular ISC2 pump seal platform, the ISC2-MW is designed with increased internal clearances that allow for greater run-out handling in top-entry mixer services, up to 0.045 of an inch. State-of-the-art thermal management reduces seal face temperatures and the internal volute groove promotes barrier fluid flow inside the seal. -

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient.

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient. -

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient.

The Ampliflow G-Boost delivers a continuous supply of clean seal gas to compressor gas seals, eliminating a source of contamination and equipment downtime. Driven by an electric motor, the Ampliflow G-Boost improves operational reliability during periods of low differential pressure across the compressor when the available seal gas supply is insufficient. -

SLC Series seals are heavy duty single cartridge seals built for the harshest slurry pump services found in mining, mineral and ore processing, and flue gas desulfurization. The SLC Series is designed with a unique non-clogging cone spring that increases seal reliability and enables flushless operation for low operating costs.

SLC Series seals are heavy duty single cartridge seals built for the harshest slurry pump services found in mining, mineral and ore processing, and flue gas desulfurization. The SLC Series is designed with a unique non-clogging cone spring that increases seal reliability and enables flushless operation for low operating costs. -

The RIS seal has a unique, non-clogging design that does not utilize springs or bellows. The innovative design of the adaptive components allows the seal to be installed from the wet-end of the pump and to be adjusted externally. With many pump designs, the seal may be reset automatically during impeller clearance adjustment.

The RIS seal has a unique, non-clogging design that does not utilize springs or bellows. The innovative design of the adaptive components allows the seal to be installed from the wet-end of the pump and to be adjusted externally. With many pump designs, the seal may be reset automatically during impeller clearance adjustment.