-

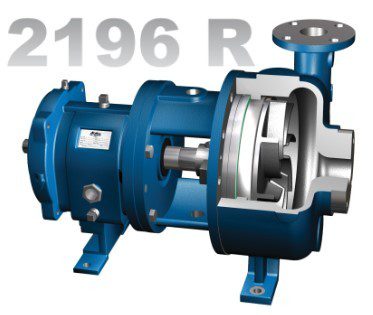

Increase the Longevity of your pump and reduce your total cost of ownership. Benefits: Advanced thermal fatigue resistance, Extended product life cycle, Thermal expansion stresses are reduced, Extended MTBF (Mean Time Before Failure). Applications: Corrosive Services, Acid & Caustics, Pharmaceuticals, Food & Beverage, Hot Oils, Chemical/Petrochemical Processing. Optional Features: Finned-Tube Oil Cooler, Multiple Stuffing Box Cover Options (Standard Bore, Large Bore, Taper Bore)

Increase the Longevity of your pump and reduce your total cost of ownership. Benefits: Advanced thermal fatigue resistance, Extended product life cycle, Thermal expansion stresses are reduced, Extended MTBF (Mean Time Before Failure). Applications: Corrosive Services, Acid & Caustics, Pharmaceuticals, Food & Beverage, Hot Oils, Chemical/Petrochemical Processing. Optional Features: Finned-Tube Oil Cooler, Multiple Stuffing Box Cover Options (Standard Bore, Large Bore, Taper Bore) -

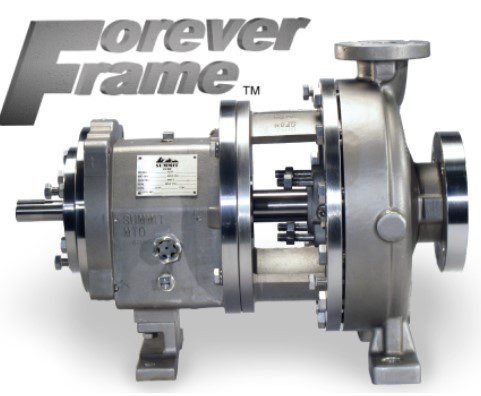

Benefits: Reduced Shaft Vibration, Lower NPSHr, Lower Seal Chamber Pressure, Extended MTBF on Pump and Mechanical Seal. Applications: Additive Chemicals, Batch/Continuous Chemical Reactors, Chemical Dryers, Chemical Processes, Condensate Service, Evaporators, Petro Chemical Service, Shower Services. Optional Features: Finned-Tube Oil Cooler, Multiple Stuffing Box Cover Options (Standard Bore, Large Bore, Taper Bore), Forever Frame.

Benefits: Reduced Shaft Vibration, Lower NPSHr, Lower Seal Chamber Pressure, Extended MTBF on Pump and Mechanical Seal. Applications: Additive Chemicals, Batch/Continuous Chemical Reactors, Chemical Dryers, Chemical Processes, Condensate Service, Evaporators, Petro Chemical Service, Shower Services. Optional Features: Finned-Tube Oil Cooler, Multiple Stuffing Box Cover Options (Standard Bore, Large Bore, Taper Bore), Forever Frame. -

Applications: Clean Water, Solvents, Light Oils, Non-Corrosive Chemicals, Coolants, Brines. CC and FM pumps and parts manufactured by Summit Pump, Inc. are functionally and dimensionally interchangeable with the Peerless® C & F line manufactured by Peerless® Pump. Part for part interchangeability means you have a quality option when sourcing pumps or parts.

Applications: Clean Water, Solvents, Light Oils, Non-Corrosive Chemicals, Coolants, Brines. CC and FM pumps and parts manufactured by Summit Pump, Inc. are functionally and dimensionally interchangeable with the Peerless® C & F line manufactured by Peerless® Pump. Part for part interchangeability means you have a quality option when sourcing pumps or parts.