-

Designed for use in the Bio-Pharmaceutical industry, the Waukesha S200 series high purity, sanitary centrifugal pumps are manufactured to ASME BPE specification criteria. All product contact components on the S200 are machined from wrought <5% ferrite level, 316L stainless steel and feature a 20 Ra product contact surface finish. Material heat numbers are available on all product contact components.

Designed for use in the Bio-Pharmaceutical industry, the Waukesha S200 series high purity, sanitary centrifugal pumps are manufactured to ASME BPE specification criteria. All product contact components on the S200 are machined from wrought <5% ferrite level, 316L stainless steel and feature a 20 Ra product contact surface finish. Material heat numbers are available on all product contact components. -

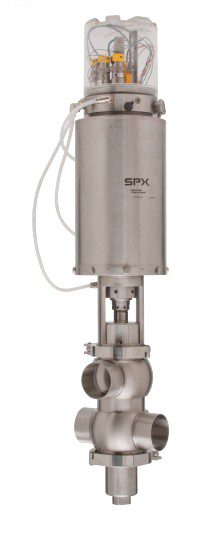

The Waukesha W60 Series sanitary single seat valves are the ultimate in easy cleaning, high pressure, low maintenance design. With 16 standard sanitary bodies, 12 different actuators, 5 stem types, and a wide range of control tops, the valves can be configured to precisely fit any application. Materials Product Wetted: ASTM 316L (UNS-S31603); (DIN-1.4404) Non-Product: : ASTM 304 (UNS-S30400); (DIN-1.4301) Seat Material: : Tef FlowTM (Std) , Options: EPDM, FKM, stainless steel, TFP Surface Finish: : 32Ra (<0.8 ?m, higher finishes are available

-

The Waukesha W68 Series sanitary valve familty of "throttling or pressure control" valves are the ultimate in: easy cleaning, high pressure, low maintenance design. With 11 standard sanitary bodies, 12 different actuators, 4 stem types, flush or standard adaptor, and a wide range of control tops, these Waukehsa valves can be configured to precisely fit any application

-

The Waukesha W70 line of sanitary mix proof valves offers an economical solution to a wide variety of mix proof processing applications. Flow of two different media through the same valve simultaneously, without the potential for mixing, provides increased operating efficiencies and significant production cost savings.

The Waukesha W70 line of sanitary mix proof valves offers an economical solution to a wide variety of mix proof processing applications. Flow of two different media through the same valve simultaneously, without the potential for mixing, provides increased operating efficiencies and significant production cost savings. -

The Waukesha W70 line of sanitary mix proof valves offers an economical solution to a wide variety of mix proof processing applications. Flow of two different media through the same valve simultaneously, without the potential for mixing, provides increased operating efficiencies and significant production cost savings.

The Waukesha W70 line of sanitary mix proof valves offers an economical solution to a wide variety of mix proof processing applications. Flow of two different media through the same valve simultaneously, without the potential for mixing, provides increased operating efficiencies and significant production cost savings. -

Waukesha Cherry-Burrell brand W45 Check Valves are 'wafer-style', where product flow pushes the valve disc away from the seat. In the absence of forward flow pressure, the electropolished spring returns the disc and holds it closed against the seat. Back flow pressure also pushes the disc into the closed position.

Waukesha Cherry-Burrell brand W45 Check Valves are 'wafer-style', where product flow pushes the valve disc away from the seat. In the absence of forward flow pressure, the electropolished spring returns the disc and holds it closed against the seat. Back flow pressure also pushes the disc into the closed position. -

Waukesha Cherry-Burrell brand 45HMP Check Valves are 'wafer-style', where product flow pushes the valve disc away from the seat. In the absence of forward flow pressure, the electropolished spring returns the disc and holds it closed against the seat. Back flow pressure also pushes the disc into the closed position.

-

Waukesha Cherry-Burrell brand 45BY Ball Check Valves have a 316L stainless steel body with a curved offset ball trap. Product flow pushes the ball up into the trap and out of the product stream for full diameter flow. This check valve is well suited to applications where there is pulsing flow and should not be used for sticky, adhesive products, or those with excessive viscosities where the ball can be held in the offset tube.

Waukesha Cherry-Burrell brand 45BY Ball Check Valves have a 316L stainless steel body with a curved offset ball trap. Product flow pushes the ball up into the trap and out of the product stream for full diameter flow. This check valve is well suited to applications where there is pulsing flow and should not be used for sticky, adhesive products, or those with excessive viscosities where the ball can be held in the offset tube. -

For installation on pump suction lines, the 40CF-AR Sanitary Air Vent Valve is designed to operate as a CIP return air relief, and operates against either vacuum or positive pressure. For proper operation, the valve should be mounted vertically. • The Waukesha 40CF-AR is available in 1"-4" sizes. S-Line connections are standard. Other connections are available on request. • The 40CF-AR has a polypropylene ball that acts between the upper and lower machined seats. The valve body is machined stainless steel, either 304 or 316 • Buna gaskets or FKM.

For installation on pump suction lines, the 40CF-AR Sanitary Air Vent Valve is designed to operate as a CIP return air relief, and operates against either vacuum or positive pressure. For proper operation, the valve should be mounted vertically. • The Waukesha 40CF-AR is available in 1"-4" sizes. S-Line connections are standard. Other connections are available on request. • The 40CF-AR has a polypropylene ball that acts between the upper and lower machined seats. The valve body is machined stainless steel, either 304 or 316 • Buna gaskets or FKM. -

Whether you need manually or pneumatically controlled butterfly valves for pipeline installation or preassembled valve manifolds, the Waukesha Cherry-Burrell 200 series from SPX FLOW is the answer. These are a robust and reliable shut-off element with a long service life. Butterfly Valves offer great durability, economy and ease of use for a wide range of applications. Easy to install and maintain, butterfly valves close under pressure to form a leak-tight seal, plus have the ability to throttle flow with a positioner.

Whether you need manually or pneumatically controlled butterfly valves for pipeline installation or preassembled valve manifolds, the Waukesha Cherry-Burrell 200 series from SPX FLOW is the answer. These are a robust and reliable shut-off element with a long service life. Butterfly Valves offer great durability, economy and ease of use for a wide range of applications. Easy to install and maintain, butterfly valves close under pressure to form a leak-tight seal, plus have the ability to throttle flow with a positioner. -

Ball valves offer great economy and durability for a wide range of applications that do not require clean-in-place (CIP) service. They are easy to install and maintain. The full ported, straight-through design of ball valves frees the flow path from obstructions. As a result, pressure drops across the valves are reduced, and there is no change in elevation for piping through the valve. This allows efficient and safe production or cleaning processes in the food, beverage, dairy, industrial, and chemical industries.

Ball valves offer great economy and durability for a wide range of applications that do not require clean-in-place (CIP) service. They are easy to install and maintain. The full ported, straight-through design of ball valves frees the flow path from obstructions. As a result, pressure drops across the valves are reduced, and there is no change in elevation for piping through the valve. This allows efficient and safe production or cleaning processes in the food, beverage, dairy, industrial, and chemical industries. -

Cesco MagTraps are North America's popular brand of magnetic separators for liquids, slurries, and pumped chunky products. These powerful magnetic line traps are available in more than 30 off-the-shelf models and an unlimited number of custom configurations when manufactured to customer specifications. Standard sizes for ½ to 6 inch lines. Metal trash and fines, including work-hardened stainless steel as small as 0.0001 inches are captured by powerful, rare-earth, neodymium magnets and held in-place until cleaned. Powered by proprietary, easy to clean, tube or plate circuits that operate to pressures of 750 PSI and temperatures of 500? F

Cesco MagTraps are North America's popular brand of magnetic separators for liquids, slurries, and pumped chunky products. These powerful magnetic line traps are available in more than 30 off-the-shelf models and an unlimited number of custom configurations when manufactured to customer specifications. Standard sizes for ½ to 6 inch lines. Metal trash and fines, including work-hardened stainless steel as small as 0.0001 inches are captured by powerful, rare-earth, neodymium magnets and held in-place until cleaned. Powered by proprietary, easy to clean, tube or plate circuits that operate to pressures of 750 PSI and temperatures of 500? F -

Sani-Matic offers the widest variety of sizes and styles of high quality sanitary Angle and Straight-Line Strainers for reliable performance. Made by our Wisconsin craftsmen, they are designed for durability and are readily available for quick delivery. Sani-Matic strainers can use perforated inserts or wedgewire interchangeably. Perforated inserts require either disposable filter socks or wire mesh overlays for fine filtration. Wedgewire offers an effective and durable single piece insert in micron ratings equivalent to wiremesh. Advantages of wedgewire are:

Sani-Matic offers the widest variety of sizes and styles of high quality sanitary Angle and Straight-Line Strainers for reliable performance. Made by our Wisconsin craftsmen, they are designed for durability and are readily available for quick delivery. Sani-Matic strainers can use perforated inserts or wedgewire interchangeably. Perforated inserts require either disposable filter socks or wire mesh overlays for fine filtration. Wedgewire offers an effective and durable single piece insert in micron ratings equivalent to wiremesh. Advantages of wedgewire are:- One piece solution

- Durable, long-lasting

- Increased pressure rating

- More sanitary than wiremesh

-

Waukesha Cherry-Burrell stainless steel filters and strainers offer sanitary, efficient flow design, flexibility in installation and quick and simple cleanup. Filters provide reliable means of removing fine particles from liquids; filtering media must be removed and disposed periodically. Strainers, on the other hand, actually are coarse filters that remove larger particles; the straining mesh can be reused after cleaning.

Waukesha Cherry-Burrell stainless steel filters and strainers offer sanitary, efficient flow design, flexibility in installation and quick and simple cleanup. Filters provide reliable means of removing fine particles from liquids; filtering media must be removed and disposed periodically. Strainers, on the other hand, actually are coarse filters that remove larger particles; the straining mesh can be reused after cleaning. -

Keep Materials Out of Pumps and Process Equipment Sani-Matic Tee-Line Strainers are designed to keep foreign materials such as gasket pieces, bolts and other items out of your pumps, valves and process equipment. They are installed before the suction end of your pump, as an economical and easy way to protect your valuable equipment. And, because the Sani-Matic Tee-Line Strainer’s open area of perforation exceeds line size diameter, there is minimal pressure drop. The Tee-Line Strainer is engineered with simplicity and durability in mind and the tri-clamp fitting allows quick and easy insert removal.

Keep Materials Out of Pumps and Process Equipment Sani-Matic Tee-Line Strainers are designed to keep foreign materials such as gasket pieces, bolts and other items out of your pumps, valves and process equipment. They are installed before the suction end of your pump, as an economical and easy way to protect your valuable equipment. And, because the Sani-Matic Tee-Line Strainer’s open area of perforation exceeds line size diameter, there is minimal pressure drop. The Tee-Line Strainer is engineered with simplicity and durability in mind and the tri-clamp fitting allows quick and easy insert removal. -

Special Construction for High-Volume Process Do you have a lot of particulate to strain from your process? Do you need a long run time without having to clean your strainer? If yes, Basket Strainers are an ideal solution for your process. Sani-Matic Basket Strainers are specially constructed to strain particulates out of high-volume process streams. The innovative design includes a side inlet, which allows you to easily remove the basket for cleaning without disconnecting the line. Its durable construction means increased longevity in the field. Sani-Matic offers both short and long models to meet your specific process needs. Our basket strainers are 3-A certified when using the perforated element. If 3-A certification is required, consult a Sani-Matic sales associate to ensure the configuration meets standards.

Special Construction for High-Volume Process Do you have a lot of particulate to strain from your process? Do you need a long run time without having to clean your strainer? If yes, Basket Strainers are an ideal solution for your process. Sani-Matic Basket Strainers are specially constructed to strain particulates out of high-volume process streams. The innovative design includes a side inlet, which allows you to easily remove the basket for cleaning without disconnecting the line. Its durable construction means increased longevity in the field. Sani-Matic offers both short and long models to meet your specific process needs. Our basket strainers are 3-A certified when using the perforated element. If 3-A certification is required, consult a Sani-Matic sales associate to ensure the configuration meets standards. -

When making sanitary manifolds, using the “fish mouth” fabrication method has many shortcomings;

When making sanitary manifolds, using the “fish mouth” fabrication method has many shortcomings;- It requires a difficult hand weld

- It is difficult to know if full penetration of the weld area has been accomplished.

- The weld is difficult to polish

- Once polished, it is impossible to tell how much wall thickness is left in the joint

-

There is a wide variety of stainless steel sanitary process connection systems used in the world. European sanitary fittings systems include DIN 11851, SMS, RJT and IDF fittings. Often, process equipment built in the Europe comes to the US with stainless steel piping using one of these connection systems. We build custom adapters to allow users to transition to sanitary clamp systems in a clean and efficient manner.

There is a wide variety of stainless steel sanitary process connection systems used in the world. European sanitary fittings systems include DIN 11851, SMS, RJT and IDF fittings. Often, process equipment built in the Europe comes to the US with stainless steel piping using one of these connection systems. We build custom adapters to allow users to transition to sanitary clamp systems in a clean and efficient manner. -

We have been designing and building sanitary flow transfer panels and sanitary utility panels for over 25 years. Our completed projects range from simple 3-ports flow diversion panels to highly complex 3 dimensional sanitary flow transfer panels with over 100 ports and electronic feedback on each circuit. Our client list consists of most of the major biopharmaceutical manufacturers in the U.S.

We have been designing and building sanitary flow transfer panels and sanitary utility panels for over 25 years. Our completed projects range from simple 3-ports flow diversion panels to highly complex 3 dimensional sanitary flow transfer panels with over 100 ports and electronic feedback on each circuit. Our client list consists of most of the major biopharmaceutical manufacturers in the U.S. -

When working with high value products, any liquid left in a piping system can be costly. We offer a line of sanitary orifices the reduce this risk when a fixed orifice pressure reduction is required in the process. Unlike most orifice plates which can leave some liquid on the upstream side of the plate, the LPE sanitary orifices are fully draining when mounted in the vertical position. The tapered interior design ensures that there will be no product hold up.

When working with high value products, any liquid left in a piping system can be costly. We offer a line of sanitary orifices the reduce this risk when a fixed orifice pressure reduction is required in the process. Unlike most orifice plates which can leave some liquid on the upstream side of the plate, the LPE sanitary orifices are fully draining when mounted in the vertical position. The tapered interior design ensures that there will be no product hold up. -

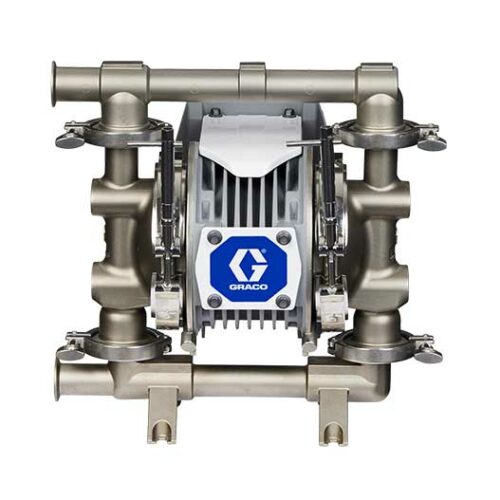

Designed to meet the growing demand for clean energy and sustainable technologies, QUANTM is the world’s first (and only) affordable electric-operated double diaphragm (EODD) pump built to minimize energy consumption by cutting energy usage and costs by up to 80%. Innovative, new FluxCore motors and drives provide up to 8x more continuous torque at low speeds while minimizing size and resistance losses. These revolutionary pumps are easy to clean, simple to maintain, and require less energy to operate—providing a lower cost of ownership. Graco's seal-less and self-priming diaphragm pump design delivers clear advantages over all other pumps, including centrifugal, lobe, gear, progressive cavity, peristatic and piston/plunger technologies.

Designed to meet the growing demand for clean energy and sustainable technologies, QUANTM is the world’s first (and only) affordable electric-operated double diaphragm (EODD) pump built to minimize energy consumption by cutting energy usage and costs by up to 80%. Innovative, new FluxCore motors and drives provide up to 8x more continuous torque at low speeds while minimizing size and resistance losses. These revolutionary pumps are easy to clean, simple to maintain, and require less energy to operate—providing a lower cost of ownership. Graco's seal-less and self-priming diaphragm pump design delivers clear advantages over all other pumps, including centrifugal, lobe, gear, progressive cavity, peristatic and piston/plunger technologies. -

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications. Unibloc Pump gear positive displacement (PD) pumps set the bar with their dynamic gearbox foundation. These PD pumps offer a solid basis for consistency and precision and provide the broadest selection of sanitary pumping solutions. Designed for the most rigorous processing and cleaning situations, Unibloc Pump is the leader in 3A sanitary applications.

The gear pump is built to last, ensuring worry-free dependability and pinpoint precision. Unibloc's gear pumps are the premier choice for 3A sanitary applications. Unibloc Pump gear positive displacement (PD) pumps set the bar with their dynamic gearbox foundation. These PD pumps offer a solid basis for consistency and precision and provide the broadest selection of sanitary pumping solutions. Designed for the most rigorous processing and cleaning situations, Unibloc Pump is the leader in 3A sanitary applications.