-

APV Lab Series Homogenizers provide the desired mean particle size and narrow, uniform distribution you need to help you improve existing products develop new ones. Two units are available to meet your laboratory requirements; operating pressures of 14,500 psi (1000bar) and 29,000 psi (2000 bar) with nominal capacities of 6 g/h (22 l/h) and 3 g/h (11 l/h) respectively. The units are ideal for a wide variety of emulsions and dispersions.

APV Lab Series Homogenizers provide the desired mean particle size and narrow, uniform distribution you need to help you improve existing products develop new ones. Two units are available to meet your laboratory requirements; operating pressures of 14,500 psi (1000bar) and 29,000 psi (2000 bar) with nominal capacities of 6 g/h (22 l/h) and 3 g/h (11 l/h) respectively. The units are ideal for a wide variety of emulsions and dispersions. -

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries. The fully hydraulically balanced design promotes a reliable valve that prevents hydraulic blocking and withstands pressure spikes, enabling flexible bi-directional non-slamming flow

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries. The fully hydraulically balanced design promotes a reliable valve that prevents hydraulic blocking and withstands pressure spikes, enabling flexible bi-directional non-slamming flow -

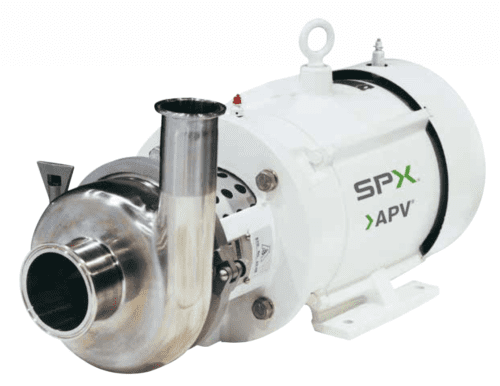

The APV model V² centrifugal pump is a simplified and maintenance-friendly pump featuring a four-blade, fully open, non-clog impeller. Enginneered for CIP cleaning, and offering a choice of five seal types, the V² pump meets 3-A sanitary standards and is suitable for applications in the food, dairy, beverage, brewing, bakery, meat, pharmaceutical and chemical industries. The back plate is machined from heavy 316 stainless steel plate; the casing has controlled wall thickness and dimensional accuracy throughout; and a clamping assembly uses investment cast clamp rings with a self-locking internal angle for optimum sealing between casing and back plate. The V² pump is available in eight sizes with capacities to 500 US GPM and heads to 300 feet. Specialty models include pedestal mount, portable bases, and complete hopper assemblies.

The APV model V² centrifugal pump is a simplified and maintenance-friendly pump featuring a four-blade, fully open, non-clog impeller. Enginneered for CIP cleaning, and offering a choice of five seal types, the V² pump meets 3-A sanitary standards and is suitable for applications in the food, dairy, beverage, brewing, bakery, meat, pharmaceutical and chemical industries. The back plate is machined from heavy 316 stainless steel plate; the casing has controlled wall thickness and dimensional accuracy throughout; and a clamping assembly uses investment cast clamp rings with a self-locking internal angle for optimum sealing between casing and back plate. The V² pump is available in eight sizes with capacities to 500 US GPM and heads to 300 feet. Specialty models include pedestal mount, portable bases, and complete hopper assemblies. -

Environmental requirements are getting strict. But today, aseptic production is already essential to certain processes - including the manufacture of long life food and pharmaceutical products. The Wa+ pump is the perfect solution. All seals, including the shaft seal, are designed as double seals. Wa+ pumps ensure absolutely aseptic production processes with barrier media up to 150°C (320°F). With a Wa+ pump, the risk of contaminating the product and environment is thus reduced to an absolute minimum.

Environmental requirements are getting strict. But today, aseptic production is already essential to certain processes - including the manufacture of long life food and pharmaceutical products. The Wa+ pump is the perfect solution. All seals, including the shaft seal, are designed as double seals. Wa+ pumps ensure absolutely aseptic production processes with barrier media up to 150°C (320°F). With a Wa+ pump, the risk of contaminating the product and environment is thus reduced to an absolute minimum. -

The inducer pump is the alternative to changing the process design when NPSH availability is low. The inducer boosts the inlet pressure, and the risk of cavitation is correspondingly reduced (the NPSH required typically drops by 50-70%). When the risk of cavitation disappears, so does the risk of a large number of operational disturbances that would otherwise result - such as excessive noise, energy loss, product damage and unnecessary wear on the pump. Low suction head is a common "problem" in miscellaneous applications, e.g. when pumping products with low boiling points or in processes that involve vacuums.

The inducer pump is the alternative to changing the process design when NPSH availability is low. The inducer boosts the inlet pressure, and the risk of cavitation is correspondingly reduced (the NPSH required typically drops by 50-70%). When the risk of cavitation disappears, so does the risk of a large number of operational disturbances that would otherwise result - such as excessive noise, energy loss, product damage and unnecessary wear on the pump. Low suction head is a common "problem" in miscellaneous applications, e.g. when pumping products with low boiling points or in processes that involve vacuums. -

The self-priming Ws+ is designed to handle Clean In Place (CIP) return and other fluids with entrained air and foam. The unique design reduces the energy consumption and noise of traditional liquid ring pumps by using a high efficiency impeller that can be trimmed to match a specific duty. The Ws+ employs a built in eccentric air screw to form the liquid ring required for its self-priming capability.

The self-priming Ws+ is designed to handle Clean In Place (CIP) return and other fluids with entrained air and foam. The unique design reduces the energy consumption and noise of traditional liquid ring pumps by using a high efficiency impeller that can be trimmed to match a specific duty. The Ws+ employs a built in eccentric air screw to form the liquid ring required for its self-priming capability.