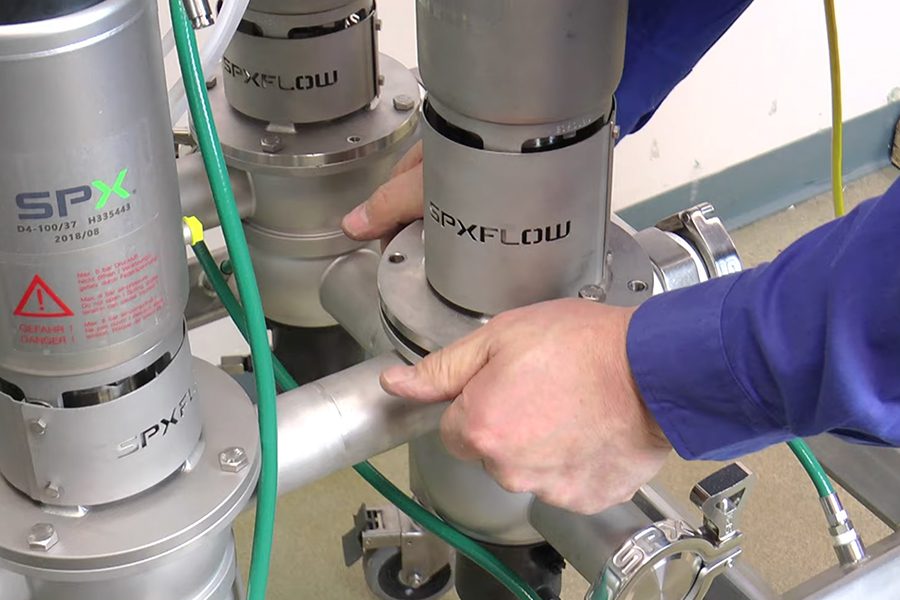

Mixproof Valve Manifolds

A mix proof valve manifold is a tight cluster of automated system of integrated mix proof valves on a supporting frame. Utilities like compressed air, I/O are consolidated into a single area. Liquid hold-up volumes are minimized. Mixproof valves that safely and efficiently route multiple products and cleaning streams in a production line, preventing cross-contamination between incompatible fluids while allowing simultaneous processing and cleaning operations. These systems are vital in hygienic industries, such as food and beverage, dairy, and pharmaceutical manufacturing, for maintaining product integrity, optimizing production time, and ensuring compliance with strict hygiene standards.

How Mixproof Valve Manifolds Work

- Automated Fluid Control: The system uses automated valves to control the flow of different liquids, acting like a “traffic cop” to direct them to their intended destinations.

- Prevention of Cross-Contamination: By using a double-valve system, product and cleaning solutions are kept separate. The valves are designed to prevent mixing of incompatible fluids, even during simultaneous operations like filling one tank while cleaning another.

- Simultaneous Operations: A single manifold can handle multiple processes at once, such as filling and emptying different tanks, while also performing a clean-in-place (CIP) cycle on another line without interruption.

- Centralized Control: The entire system can be controlled remotely via a PLC (Programmable Logic Controller) and may include integrated sensors, solenoids, and a fieldbus interface for status display and operation.

Key

Benefits:

- Enhanced Productivity: By enabling simultaneous production and cleaning, Mixproof Valves reduce cleaning and downtime, increasing production time and revenue. Mixproof manifolds significantly increase production reliability and repeatability, reduce downtime and maximize production capacity.

- Engineering Support: LPE Engineers can design the process P&ID for the valves, design and fabricate the complete manifold weldment. An Approval Drawing Process is used to ensure the finished product reflects your needs.

- Improved Safety & Hygiene: The elimination of cross-contamination is crucial for maintaining the safety and quality of products, especially in food, dairy, and pharmaceutical applications.

- Increased Flexibility: Mixproof valve manifolds allow for flexible process management, allowing for easy changes in production routes and sequences.

- Automation: The system provides a safe, flexible, and automated alternative to manual hose systems, improving efficiency and reducing manual labor.

Common

Applications:

- Product types from spirits to baby food.

- Hygienic, ultra-clean and aseptic systems

- Fluid tanker receiving, cleaning, transfer to storage.

- Tank and line Clean-In-Place (CIP) systems.

- Raw and pasteurized product routing.

- Fluid-based to sugar-based liquids routing.

- High-temperature, short-time systems.

- Extended shelf-life systems.

Featured Product:

D4 Series Double Seat Mixproof Valves

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries.

Maintenance

Mixproof valves are highly regarded for their extended product life cycle, simplicity of maintenance, and ready availability of spare parts. The total cost of ownership is notably lower than that of conventional valves, and these systems are designed for straightforward access and maintenance.

Equipment & System Design

LPE offers comprehensive solutions, serving as your sole point of accountability for performance, schedule, and budget adherence. Our commitment is to tailor your system precisely to your unique specifications, crafting it for seamless integration into both new and existing systems.

The choice of the most suitable valve technology hinges on the specific attributes of your product. Our dedicated engineers ensure that your system:

- Provides the necessary safety standards for your product.

- Facilitates efficient plant operations and performance.

- Contributes to a lower overall cost of ownership.

What Our Customers Have to Say…

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator